- Home

- About us

- Products

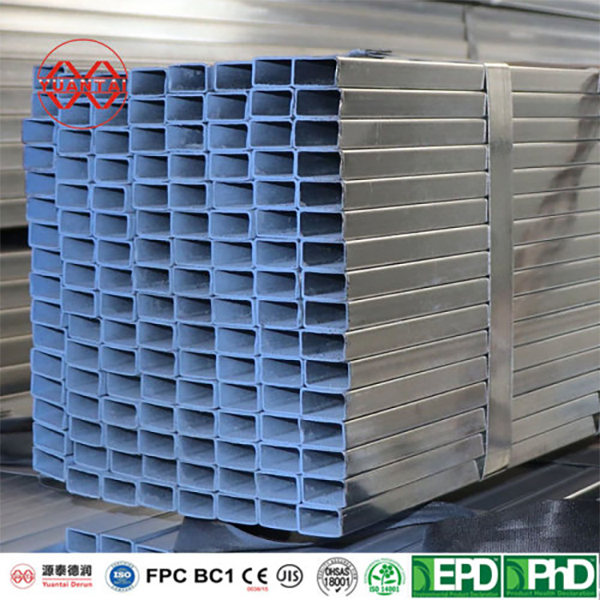

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

Which-kind-Surface-coating-for-carbon-steel-pipe?

1.carbon-steel-pipe Anti-rusted oil painting,

The rust problem of carbon steel pipes is mainly caused by long-term exposure to the air, so some measures can be taken for surface treatment, such as painting and galvanizing.

Painting can form a protective film on the surface of carbon steel pipes, which plays a role in corrosion prevention and beauty;

2.steel pipe varnish painting

Varnishing the surface of carbon steel pipes is a common anti-corrosion protection measure, which can effectively extend the service life of the pipeline.Benefits of varnish coating

Extended life: Significantly improves the corrosion resistance of carbon steel pipes and reduces maintenance costs.

Increased value: Good appearance helps to enhance the market competitiveness of products.

Widely adaptable: Suitable for a variety of application scenarios, from industrial facilities to civil buildings.

3.Carbon steel pipe surface galvanizing

Galvanizing Process

Common galvanizing processes include hot-dip galvanizing (HDG), electro-galvanizing (EG) and mechanical galvanizing. Among them, hot-dip galvanizing is the most commonly used method because it provides a thicker and more uniform zinc layer with excellent durability and corrosion resistance.

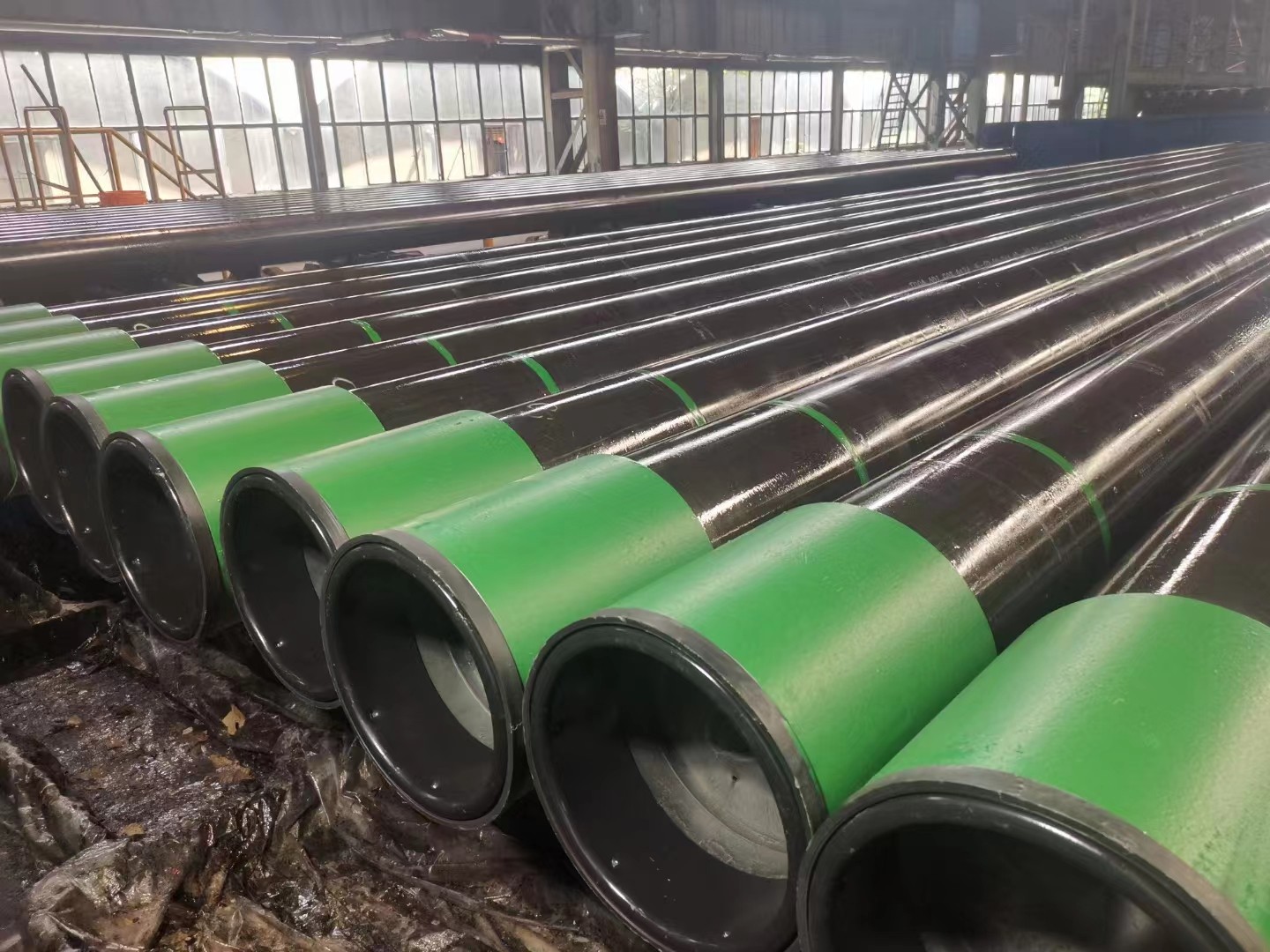

4.3LPE /3PP coated welded carbon steel pipe

Three-layer polyethylene (3LPE, Three-Layer Polyethylene) coated welded carbon steel pipe is a high-performance anti-corrosion pipeline widely used in long-distance transmission pipelines in the oil and gas, chemical, water supply and drainage industries.

Three-layer polypropylene (3PP, Three-Layer Polypropylene) coated welded carbon steel pipe is a high-performance anti-corrosion pipeline widely used in long-distance transmission pipelines in the oil and gas, chemical, water supply and drainage industries. The 3PP coating structure is similar to 3LPE, but it uses polypropylene material and has unique performance characteristics.