- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

What shipping method YUANTAI DERUN use?

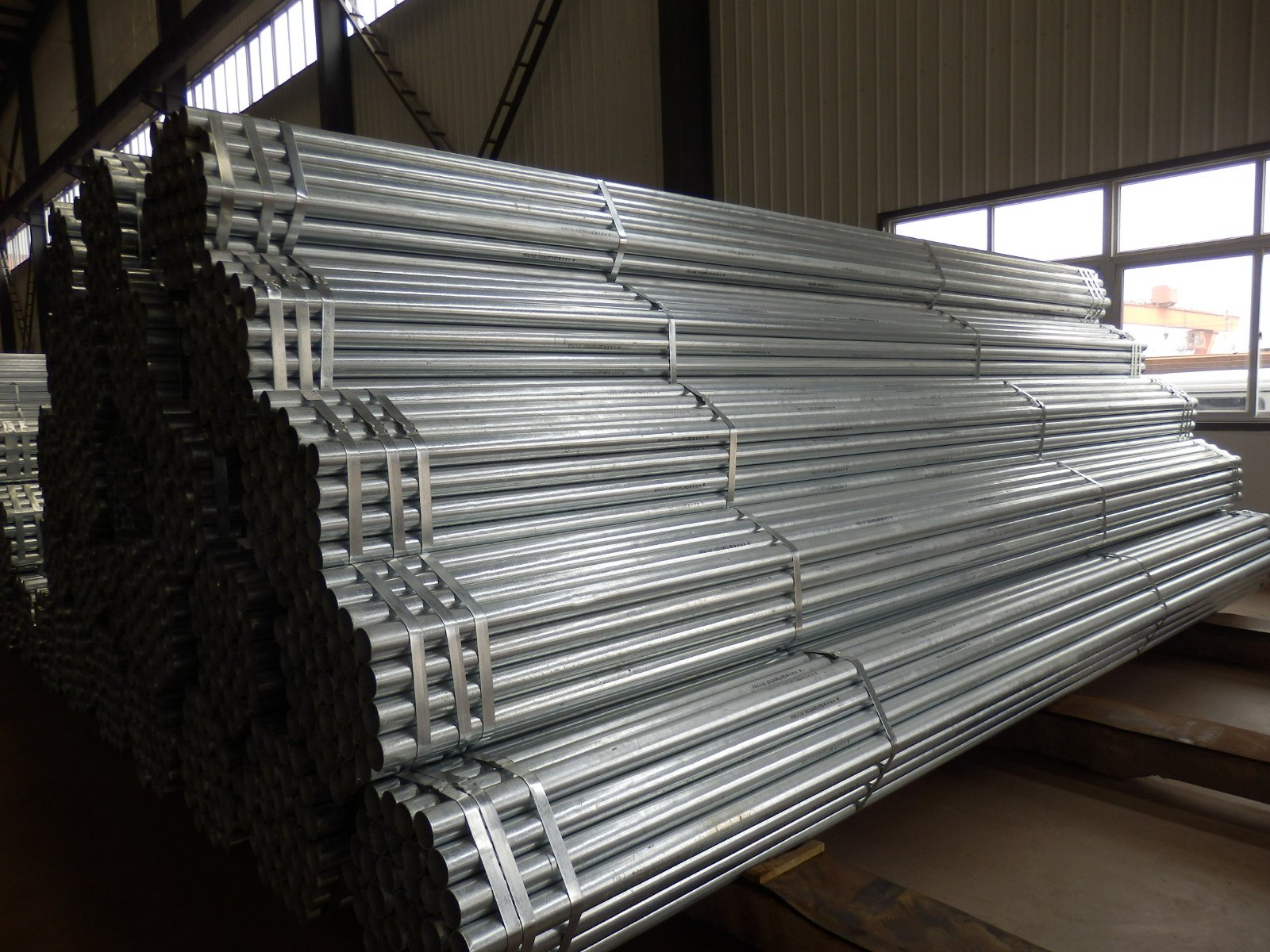

Galvanized steel pipe logistics transportation-transportation requirements

1. The carriage should be clean and free of stones, bricks and other hard objects to prevent them from hurting the steel pipes.

2. For bulk or bundled steel pipes, sleepers should be placed at the bottom of the carriage. Vehicles using flatbed trucks with steel structure brackets must be equipped with protective rubber pads on the full length of the side in contact with the steel pipe.

3. When steel pipes (or pipe bundles) are transported and delivered to the warehouse within the factory area, steel pipes (or pipe bundles) should be properly placed with isolation sleepers, at least two places along the length of the steel pipes. The sleepers should be placed vertically to the steel pipes and aligned up and down. The sleepers should be placed horizontally and intact.

4. For finished steel pipes delivered to users over long distances, they should be tied firmly after loading. If they are tied with wire ropes or similar hard objects, protective isolation materials should be placed at the steel pipe tying place or protective isolation materials should be installed on the wire ropes to prevent damage to the steel pipe surface and avoid direct collision, friction and forward and backward movement between the steel pipes and the carriage.

Galvanized steel pipe logistics transportation-packaging requirements

The packaging requirements of steel pipes are basically divided into two categories: one is ordinary bundling, and the other is loading with containers similar to turnover boxes

1. Bundling and packaging

1.1 Steel pipes should be protected from damage during bundling and transportation, and the bundling labels should be unified and consistent.

1.2 The same bundle of steel pipes should be steel pipes of the same furnace number (batch number), the same steel grade, and the same specification. Mixed furnaces (batches) should not be bundled, and less than one bundle should be bundled into small bundles.

1.3 The weight of each bundle of steel pipes should not exceed 50kg. The bundle weight can be increased with the user's consent, but the maximum weight cannot exceed 80kg.

1.4 When bundling flat-end steel pipes, one end should be aligned, and the difference between the aligned ends is less than 20mm. The length difference of each bundle of steel pipes is less than 10mm, but the length difference of each bundle of steel pipes ordered according to the usual length is less than 5mm, and the longest and second longest in a bundle of steel pipes does not exceed 10mm.

2. Bundling form

2.1 If the length of the steel pipe is greater than or equal to 6m, each bundle shall be tied with at least 8 straps, divided into 3 groups, tied in 3-2-3; if the length of the steel pipe is less than 6m, each bundle shall be tied with at least 5 straps, divided into 3 groups, tied in 2-1-2; if the length of the steel pipe is greater than or equal to 3m, each bundle shall be tied with at least 3 straps, divided into 3 groups, tied in 1-1-1.

If there are special requirements, 4 plastic clasps or nylon rope loops can be added to a single steel pipe. The clasps or rope loops should be tied firmly and should not be loose or fall off during transportation.

Galvanized steel pipe logistics transportation-packaging precautions

1. When choosing the packaging material, pay attention to the firmness and tensile strength of the material, and it should have thickness to protect the hot-dip galvanized pipe.

2. When packing, pay attention to the tension of the packaging tape and the rope, and do not be too tight or too loose to avoid affecting the shape of the hot-dip galvanized pipe.

3. When packing, pay attention to the gap between the pipe and the packaging material to avoid movement and collision of the pipe.

4. Pay attention to the influence of the external environment when packaging, and pay special attention to the firmness and moisture-proof measures of the packaging in humid, high-temperature, high-pressure and other environments.

5. The packaged hot-dip galvanized pipes should be placed in a dry, ventilated, and cool place, and should be avoided from direct sunlight to avoid affecting the quality of the pipes.

Galvanized steel pipe logistics transportation-vehicle selection

Depending on the length and quantity of the steel pipe, different types of transportation vehicles can be selected. For shorter steel pipes, flatbed trucks or container trucks can be selected for transportation; for longer steel pipes, trucks or trailers with sufficient length need to be selected for transportation. In addition, vehicles with shock absorption functions can also be considered to reduce the risk of vibration and damage to the steel pipe during transportation.

Galvanized steel pipes have high requirements for transportation vehicles due to their heavy weight, long length, and easy rust. When choosing a transportation vehicle, we need to comprehensively consider factors such as the specifications, quantity, transportation distance, and road conditions of the steel pipes.

Large flatbed trucks: Large flatbed trucks are an ideal choice for large-scale transportation of galvanized steel pipes. They have strong carrying capacity, can load multiple steel pipes, and have good stability during transportation, which can ensure the safety of the steel pipes. In addition, large flatbed trucks are also suitable for long-distance transportation and can meet the needs of cross-regional or cross-national transportation.

Special steel pipe transport vehicle: Special steel pipe transport vehicles are specially designed transportation vehicles according to the specifications and characteristics of steel pipes. Such vehicles are usually equipped with special fixing devices and anti-skid measures to ensure the stability and safety of steel pipes during transportation. At the same time, special steel pipe transport vehicles can also be flexibly adjusted according to the length and quantity of steel pipes to achieve efficient transportation.

Container transportation: For galvanized steel pipes in small quantities or that require frequent transshipment, container transportation can be used. Container transportation has the advantages of convenient loading, safe transportation, and flexible transshipment, which can reduce losses and risks during transportation. At the same time, container transportation can also achieve multimodal transportation and improve transportation efficiency.