- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

Technical specification for prefabricated construction of rectangular steel tube concrete structures

publisherTianjin Yuantai Derun Steel Pipe Manufacturing Group Co., Ltd.

time2023/07/11

- Rectangular steel tube concrete structure is a new type of structure with advantages such as high strength, good durability, and so on, gradually becoming a favorite in the field of architecture.

Technical specification for prefabricated construction of rectangular steel tube concrete structures

1、 Preface

Rectangular steel tube concrete structure is a new type of structure with advantages such as high strength, good durability, and short construction period, gradually becoming a favorite in the field of architecture. However, traditional construction methods have problems such as complex manual operations, long construction periods, and difficulty in ensuring quality. Therefore, assembly construction technology has emerged. This article aims to explore the assembly construction technology of rectangular steel tube concrete structures, providing reference for relevant practitioners.

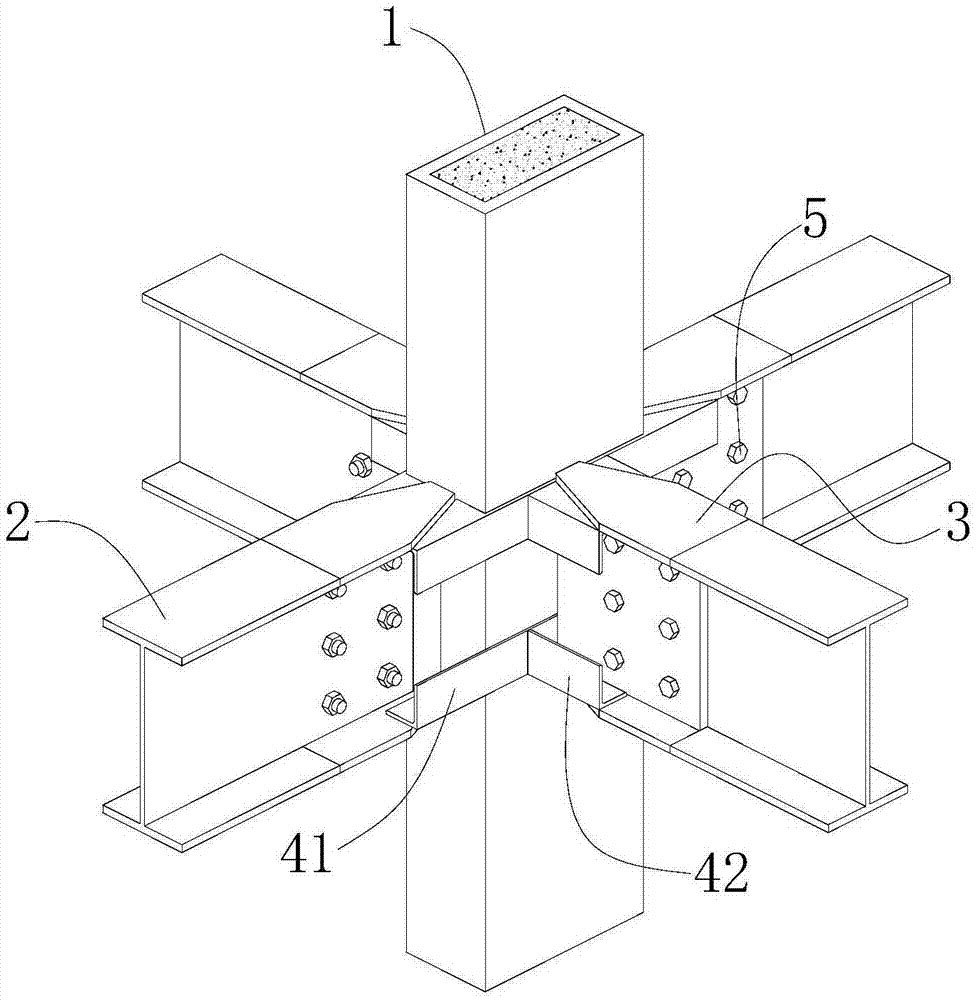

(1.)Composition of rectangular steel tube concrete structure

The rectangular steel tube concrete structure is composed of rectangular steel tubes and concrete, where rectangular steel tubes are the skeleton of the structure and concrete is the filling material. Generally, prefabricated rectangular steel pipes are used, embedded in the ground, and then sprayed with concrete to form an overall structure.

(2.)Basic principles of assembly construction technology

Assembly construction technology is the process of making building components in a factory and transporting them to the site for assembly, in order to achieve fast, efficient, and accurate construction results. The basic principle is to modularize the construction process, standardize building components, then carry out precision manufacturing in the factory, and finally perform fast and simple assembly on site.

3、 Application of Assembled Construction Technology

(1.) Factory prefabrication

The prefabrication of rectangular steel tube concrete structures is a key link in construction. Firstly, it is necessary to develop a prefabrication plan based on the actual situation, and determine the quantity and specifications of prefabricated components. Then, the rectangular steel pipe is processed, cut and welded into prefabricated components. Finally, concrete spraying is carried out in the factory to form an overall structure.

(2.)Transportation and installation

Before transportation, it is necessary to inspect the prefabricated components to ensure that their quality meets the requirements. Then, transport the prefabricated components to the site for assembly. During the assembly process, it is necessary to pay attention to the installation sequence and position of the components to ensure the stability and safety of the overall structure.

(3.)Site construction

Before conducting on-site construction, it is necessary to clean and prepare the construction site. Then, based on the installation of the prefabricated components, concrete spraying and grouting are carried out. During the construction process, it is necessary to pay attention to the proportion and construction technology of concrete to ensure the quality and strength of the concrete.

4、 Advantages of prefabricated construction technology

(1.)Short construction period

By using assembly construction technology, building components can be prefabricated in the factory and then transported to the site for assembly, greatly shortening the construction cycle.

(2.)Controllable quality

By adopting assembly construction technology, building components can be precisely manufactured in the factory, ensuring that the quality of the components meets the requirements, thereby ensuring the quality and safety of the overall structure.

(3.)Environmental protection and energy saving

Adopting assembly construction technology can reduce on-site construction noise and dust, and reduce the impact of construction on the environment. Meanwhile, due to the advanced production equipment in the factory, it can save energy and raw material usage.

5、 Conclusion

Overall, prefabricated construction technology is of great significance for the construction of rectangular steel tube concrete structures. Through factory prefabrication, transportation and installation, on-site construction and other processes, the construction cycle can be greatly shortened, construction efficiency can be improved, construction quality and safety can be guaranteed, and it is also beneficial for environmental protection and energy conservation. Therefore, practitioners in the construction industry can consider adopting prefabricated construction technology to improve the competitiveness and market share of enterprises.

If you have any technical questions about the rectangular steel tube concrete structure, please contact our customer manager immediately