- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

A New Step Forward — Inside Yuantai Derun’s JCOE Pipe Production Process

time2025/10/24

- Yuantai has achieved another breakthrough in JCOE pipe manufacturing.

The JCOE pipeline at our Tangshan base is equipped with advanced technology, ensuring enhanced efficiency, consistent quality and reliable performance.This article provides a look at the JCOE manufacturing process, detailing how Yuantai utilizes a sophisticated process involving forming, expanding, and testing to transform steel plates into high-quality welded pipes, setting a new standard in innovative steel pipe production.

A New Step Forward — Inside Yuantai Derun’s JCOE Pipe Production Process

Tianjin Yuantai Derun Group's JCOE Φ1420 Straight Submerged Arc Welding Unit, with an investment of around 80 million yuan, is now fully operational. The product has been met with great approval by our customers due to its high precision, fast production speed and consistent quality.

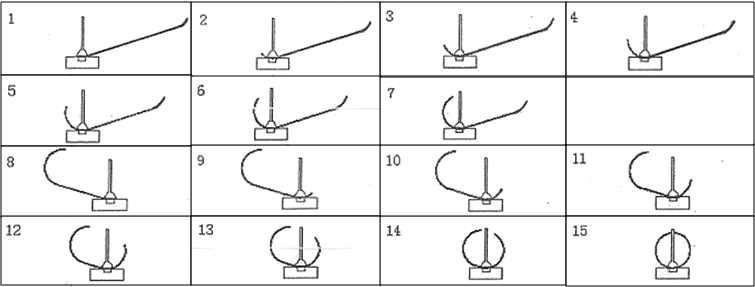

JCOE is a kind of pipe-making technology for producing large-diameter thick-walled steel pipes. It mainly uses double-sided submerged arc welding production technology. The products are subjected to milling, pre-bending, bending, jointing, internal welding, external welding, straightening, flat head Wait for multiple processes. The forming process can be decomposed into N + 1 steps (N is a positive integer), the steel plate is automatically fed laterally and bent according to the set step size, and the CNC progressive J-C-O forming is realized. The steel plate enters the forming machine in the transverse direction, and is driven by the feeding trolley to perform multi-step bending with N / 2 steps in the first stage to realize the "J" forming of the first half of the steel plate and the second stage first makes the "J" forming. The steel plate is quickly fed to the designated position in the horizontal direction, and the unformed steel plate is bent at another step of N / 2 steps from the other end to realize the forming of the second half of the steel plate and the "C" forming is completed. Finally, the lower part of the "C" tube blank is bent once to realize the "O" forming, and each step of stamping is based on the three-point bending principle.

JCOE steel pipes play an important role in large pipeline projects, water and gas transmission projects, urban pipeline network construction, bridge piling, municipal construction and urban construction. In recent years, as a new type of energy-saving and environmentally friendly building system, steel structure buildings have been hailed as "green buildings" in the 21st century. In more and more high-rise and super high-rise building design schemes, the steel structure or steel-concrete structure system is preferentially adopted, and the large-span buildings actively adopt space grid structure, three-dimensional truss structure, cable-membrane structure and prestressed structural system All of these have made steel pipes gain more application scenarios in construction projects, and the demand for large-diameter, ultra-thick wall steel pipes has also increased significantly.

Tianjin Yuantai Derun Group JCOE Φ1420 unit can produce specifications ranging from Φ406mm to Φ1420mm, and the wall thickness can be up to 50mm. After it is put into production, it will make up for the gap in the Tianjin market of such products. Ordering period of rectangular tube products. The double-sided submerged arc welding(DSAW)large straight seam welded pipe can be directly used for oil and gas transportation. While JCOE (a production procress of LSAW steel tubes) steel pipe was widely used in the national "West-to-East Gas Pipeline" project. At the same time, it can be used as a structural steel pipe in the construction of super high-rise steel structure projects. The "round to square" process can be processed into ultra-large-diameter, ultra-thick-walled rectangular steel pipes, which are applied to large-scale amusement facilities and heavy machinery and equipment manufacturing.