- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

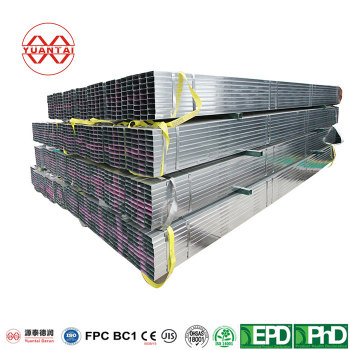

china erw pre galvanized square tube

- group name

- Pre Galvanized Steel Tube

- Min Order

- 5 ton

- brand name

- Yuantai Derun Steel Pipe Manufacturing Group

- model

- pre galvanized square tube

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Thu, 26 Feb 2026 10:55:04 GMT

Paramtents

Thickness 0.5- 16mm

OD(Outer diameter) 10*10-200*200mm

Certification CE,LEED,BV,PHD&EPD,BC1,EN10210/10219,ISO9000

Tolerance as required

Length 0.5-24M according to client requirement

Standards ASTM A500/A501,EN10219/10210,jis G3466

Materials Gr.A,Gr.B,Gr.C,S235,S275,S355,S420,S460, A36,

Delivery Time 7-30 Days

Packging & Delivery

-

Min Order5 ton

Briefing

Expand your business reach with Premium Pre-Galvanized Square Pipes: Offering OEM/ODM Solutions to Empower Global Brands.

Detailed

China ERW Pre Galvanized Square Tube

Pre Galvanized Square Tube

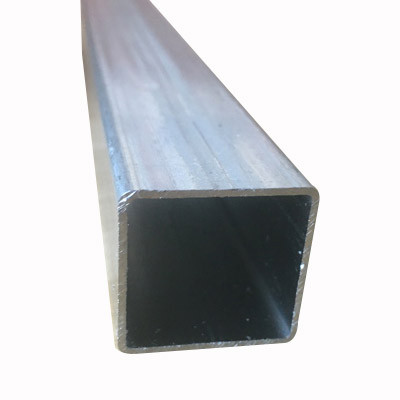

The ERW Pre Galvanized Square Tube is a square hollow section made of pre galvanized steel coils using the ERW production process.

The use of pre galvanized square tubes in various industries, such as construction and transportation, has been on the rise in recent years. Yuantai Derun is a large China ERW Pre Galvanized Square Tube Factory. ERW pre galvanized square tube has the advantages of strong anti-corrosion ability, lightweight, affordable price, and beautiful appearance.

Pre Galvanized Square Tube Advantage

1. Uniform zinc layer thickness: Unlike hot-dip galvanized square tubes, generally hot-dip galvanized pipes are prone to uneven zinc layer at the pipe mouth, weld seam, etc., while pre galvanized square steel tubes have uniform zinc layer thickness and smooth surface.

2. Efficiency and Environmental Protection: Compared to hot-dip galvanized square pipes, pre galvanized square steel pipes have environmentally friendly and efficient production processes. Hot dip galvanized square tubes require multiple processes.

3. Convenient construction: Compared with hot-dip galvanized square pipes, pre galvanized square tubes do not require additional treatment before installation, making construction more convenient and efficient.

Complete Pre Galvanized Square Tube Size For You

The Pre galvanized square tube produced by Yuantai Derun has a relatively complete range of specifications, and customers can also flexibly customize the caliber, wall thickness, length, etc. The following are some dimensions of pre galvanized square tubes. If you need to know more specifications of pre galvanized square tubes, please contact us immediately.

|

Type

|

Outer Diameter(mm)

|

Wall Thickness(mm)

|

Length(M)

|

|

ERW Pre Galvanized Square Tube

|

10*10-200*200 or Customized

|

0.5-16 or Customized

|

0.5-24 or or Customized

|

Free Pre Galvanized Steel Square Tube Samples For You

In order to provide customers with more reliable procurement, Yuantai Derun has launched a free sample policy. For pre galvanized square tube samples with a length of less than 20 centimeters, we can provide free samples for buyers. Customers only need to pay one shipping fee. Get free shipping immediately.

Pre Galvanized Square Tube Making Process

The pre galvanized square tube produced by Yuantai Derun adopts advanced production technology, and the following are the main production steps:

Galvanized Coil Uncoiling

Edge Trimming Welding

Straightening

High Frequency Welding

Cutting

Storage

Application

Pre Galvanized Square tubes are widely used in different industries due to their structural strength and versatility. Some common applications of per galvanized square steel tubes include:

Construction: Pre Galvanized Square tubes are used in the construction of buildings, bridges, and other structures due to their strength and stability.

Transportation: Pre galvanized Square tubes are used in the manufacturing of vehicle frames, trailers, and other transportation equipment.

Furniture manufacturing: Pre galvanized Square steel pipes are used in the production of furniture frames and supports.

Agricultural equipment: Pre galvanized Square steel tubes are used in the manufacturing of agricultural machinery and equipment.

Comparing Pre-Galvanized And Hot-Dip Galvanized Pipes

While pre-galvanized square tubes offer corrosion resistance, hot-dip galvanized pipes provide a higher level of protection due to the immersion of the entire pipe in molten zinc. Hot-dip galvanized tubes are commonly used in applications where extreme corrosion resistance is required, such as marine environments or highly corrosive chemical environments.

FAQs

1. Are pre galvanized square steel tubes stronger than regular square pipes?

Pre-galvanized square steel tubes offer similar levels of strength as other square pipes made from identical materials. The galvanization process primarily enhances the corrosion resistance of the pipes.

2. Can pre-galvanized square pipes withstand harsh weather conditions?

Yes, pre-galvanized square pipes are designed to withstand various weather conditions, including rain, snow, and extreme temperatures. The zinc coating acts as a protective barrier against rust and corrosion.

3. Can I weld pre galvanized square tubes?

Yes, pre-galvanized square pipes can be welded. However, it is essential to follow proper welding techniques and use appropriate welding materials to maintain the integrity of the zinc coating.

4. Are pre-galvanized square tubes suitable for outdoor applications?

Yes, pre galvanized square tubes are commonly used in outdoor applications due to their corrosion resistance. However, in highly corrosive environments, the use of hot-dip galvanized pipes may be more appropriate.

5. Can pre-galvanized square tubes be recycled?

Yes, pre-galvanized square tubes can be recycled. The steel can be melted down and reused to create new products, making it an environmentally friendly choice.