- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

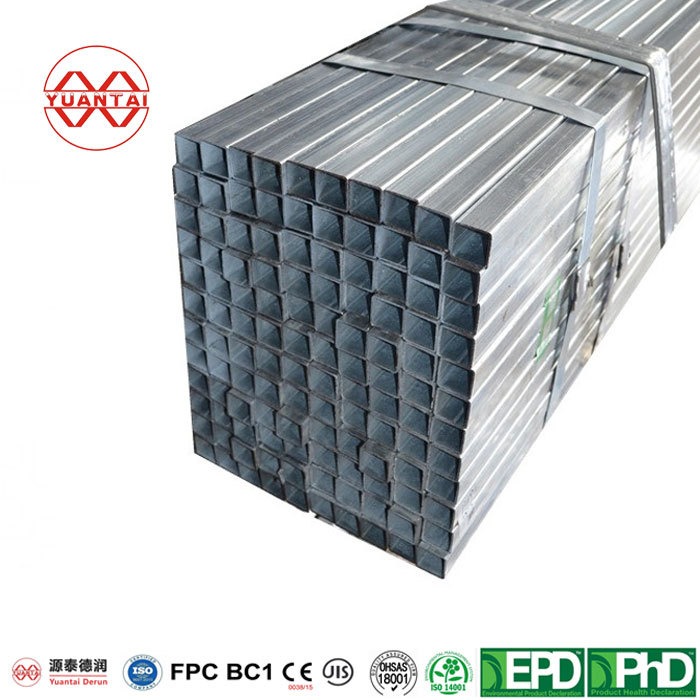

EN10219 pre galvanized zinc coating square steel pipe

- group name

- Pre Galvanized Steel Tube

- Min Order

- 5 ton

- brand name

- Yuantai Derun Steel Pipe Manufacturing Group

- model

- EN10219 pre galvanized square tube

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Sun, 21 Dec 2025 19:00:49 GMT

Paramtents

Thickness 0.5- 16 mm

OD(Outer diameter) 10*10-200*200mm

Certification CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

Tolerance as required

Length 0.5-24M according to client requirement

Standards EN10219

Delivery Time 7-30 Days

Packging & Delivery

-

Min Order5 ton

Briefing

Discover our EN10219 pre galvanized zinc coating square steel pipe, the perfect solution for your construction needs.

Detailed

EN10219 Pre Galvanized Zinc Coating Square Steel Pipe

EN10219 Pre Galvanized Square Steel Tube

EN10219 pre galvanized square steel tube, also known as galvanized strip square tube, is a high-quality galvanized square steel tube that meets the EN10219 standard. Its corrosion resistance, strength, toughness, plasticity, and weldability are relatively moderate, making it a commonly used material widely used in manufacturing machinery, automobiles, electronic devices, and many other fields. Send Your Inquiry Now!

EN10219 Pre Galvanized Square Pipe Making Process

1. Uncoiling

Select galvanized steel coils that meet the EN10219 standard for quality and performance as raw materials, carefully inspect the surface smoothness, width, batch number, and other production records of the steel strip, and record them in a book for quality traceability. Place the galvanized coil on the uncoiling equipment for uncoiling.

2. Edge trimming and butt welding:

Cut off the irregular or unqualified edge parts of the galvanized strip head, trim the heads of the two rolls and perform butt welding. After welding, manually check whether the welding is firm.

3. Straightening:

The connected galvanized strip is sent to the straightening machine equipment for straightening

4. Roll cold forming:

Galvanized strip steel is fed into a continuous forming roll equipment for continuous rolling of the shape, forming a square section without welding. The weld seam of this square section is a straight line.

5. High frequency resistance welding:

Align the welding head with the straight weld seam of the square section for high-frequency resistance welding, and use the skin effect and proximity effect to firmly weld the flux and weld seam into a whole.

6. Remove welding bars:

The welded square tube needs to remove excess welding bars quickly while it is hot to ensure the beauty and uniformity of the welded pipe weld.

7. Calibration:

The welded square tube is subjected to secondary sizing to ensure that the size meets customer requirements.

8. Water cooling:

Use clean water to cool the welded square tube.

9. Cutting:

Cut the length according to customer requirements.

10. Inspection:

Manual inspection is carried out, such as appearance, straightness, and size. Unqualified pre galvanized square pipes are picked out, and Yuantaide Run will also pick out the joint pipes.

11. Spray label storage:

Spray label according to customer requirements, then package and store for shipment. Please note that Yuantai Derun has strict packaging standards. To learn more about specific packaging standards, please click here: Packaging Standards

Achievable EN10219 Pre Galvanized Square Tubing Sizes

|

Name

|

Outer Diameter(MM)

|

Wall Thickness(MM)

|

Length(M)

|

|

EN10219 Pre Galvanized Square Tubing

|

10*10-200*200

|

0.5-16

|

0.5-24M

|

|

Or accept flexible customization

|

Or accept flexible customization

|

Or accept flexible customization

|

EN10219 Pre Galvanized Square Steel Tube Test

EN10219 Pre Galvanized Square Steel Tube can generally undergo the following testing items to ensure that the pre galvanized square tube meets the EN10219 standard.

1. Yield strength testing

2. Tensile strength testing

3. Impact test

4. Chemical composition testing

5. Hardness testing

6. Zinc layer thickness detection

7. Appearance, size, straightness testing, etc. Contact Us Now!

Free EN10219 Pre Galvanized Square Steel Tubing Samples For You

In order to facilitate customers to quickly see the EN10219 Pre Galvanized Square Steel Tubing quality, we can also provide free samples to buyers. The sample length should be within 20 centimeters, and you only need to pay one shipping fee. Get free samples immediately.

EN10219 Pre Galvanized Square Steel Pipe Authoritative Certification

The EN10219 Pre galvanized square steel pipe produced by Yuantai Derun has authoritative EN10219 product certification. In addition, the testing agency of Yuantai Derun Group, Bosi Testing, is also a CNAS certified national laboratory. Users can purchase with confidence.

EN10219 Chemical Composition Of Pre Galvanized Square Tubes

Steel Grade | % by mass, maximum | |||||

C | Si | Mn | P | S | Nb | |

|

S235JRH

|

0.17 | - |

1.40

|

0.040 |

0.040

|

0.009

|

|

S275J0H

|

0.20 | - |

1.50

|

0.035 |

0.035

|

0.009

|

|

S275J2H

|

0.20 | - |

1.50

|

0.030 |

0.030

|

-

|

|

S355J0H

|

0.22 | 0.55 |

1.60

|

0.035 |

0.035

|

0.009

|

S355J2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | - |

S355K2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | - |

EN10219 Pre Galvanized Square Tubes Mechanical Properties

|

Steel Grade

|

Minimum yieldstrength (MPa) | Tensile strength (MPa) | Minimum elongation(%) | Minimum impact energy(J) |

||||

Specified thickness (mm) | Specified thickness (mm) | Specified thickness (mm) | at test temperature of | |||||

≤16 | >16 ≤40 | <3 | ≥3 ≤40 | ≤40 |

-20°C

|

0°C

|

20°C

|

|

S235JRH | 235 | 225 | 360-510 | 360-510 | 24 | - | - | 27 |

S275J0H | 275 | 265 | 430-580 | 410-560 | 20 | - | 27 | - |

S275J2H | 27 | - | - | |||||

|

S355J0H

|

355 | 345 | 510-680 | 470-630 | 20 |

-

|

27

|

-

|

|

S355J2H

|

27

|

-

|

-

|

|||||

S355K2H | 40 | - | - | |||||

En10219 Pre Galvanized Zinc Coating Square Steel Pipe Application

En10219 Pre Galvanized Zinc Coating Square Steel Pipe is used for those industries,such as:

1. Decoration and Renovation

2. Building structure

3. Shelves

4. Mechanical manufacturing

5. Fences and guardrails

6. Factory building

7. Outdoor lamp post

8. Prefabricated buildings