- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

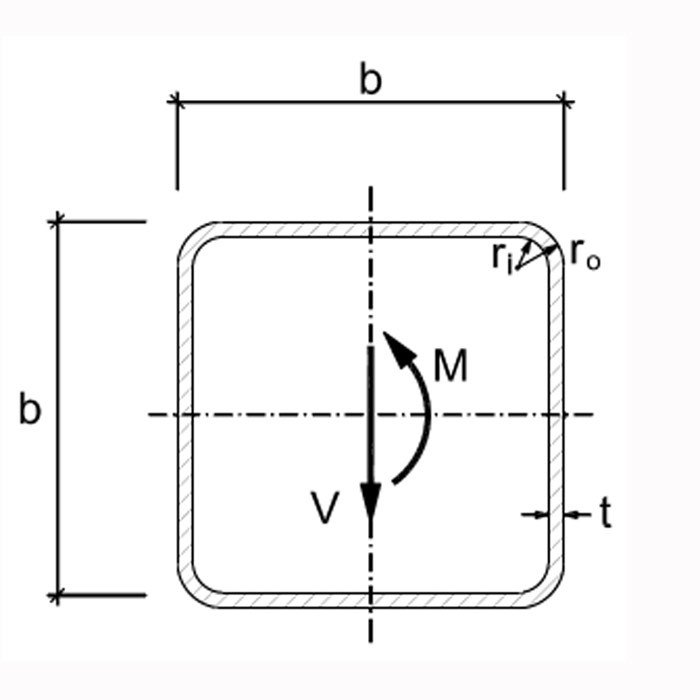

rounded square tube| Low carbon steel

- group name

- square steel pipe

- Min Order

- 5 ton

- brand name

- Yuantai Derun Steel Pipe Manufacturing Group

- model

- Square Tubes Round Corners

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Mon, 22 Dec 2025 22:55:44 GMT

Paramtents

Thickness 0.5- 60 mm

OD(Outer diameter) 10*10-1000*1000mm

Certification CE,LEED,BV,PHD&EPD,BC1,EN 10210,EN10219,ISO9000

Tolerance as required

Length 0.5-26.5M according to client requirement

Standards ASTM A500/A501,EN10219,EN10210

Materials Gr.A, Gr.B, Gr.C, S235, S275, S355,S420,S460, A36,

Delivery Time 7-30 Days

Packging & Delivery

-

Min Order5 ton

Briefing

Detailed

Rounded Square Tube

Steel Square Tube / Tubing Radius Corner

Complete Square Tubes Round Corners Sizes

Steel Square Radius Tube Coating

Added Service

Hot Finished

Sometimes, in order to better remove the stress inside the rounded square steel, customers need to perform heat treatment on the steel pipe. At Yuantai Derun, we have two heat treatment methods: tube body four corner heating and heating furnace heating, both of which can meet the requirements of removing internal stress. If you also have concerns about stress, please contact us immediately.

Punching

Free Rounded Square Tube Samples For You

Application

Project