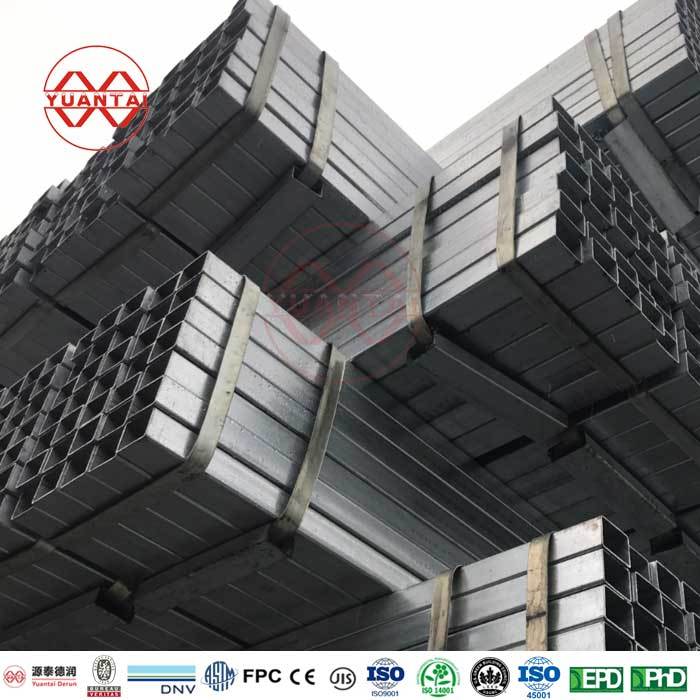

Discover the power of square steel tubes with Yuantaiderun. Your go-to manufacturer for OEM, ODM, and wholesale solutions.

HSS Square Tube: Revolutionizing Steel Structures and Beyond

In this article, we will delve into the world of HSS (Hollow Structural Sections) square tubes, exploring their characteristics, applications, weight calculations, size charts, carrying capacities, pricing factors, and more. HSS square tubes have gained significant popularity in various industries for their exceptional strength, durability, and versatility. Join us as we uncover the fascinating details of this revolutionary steel product.

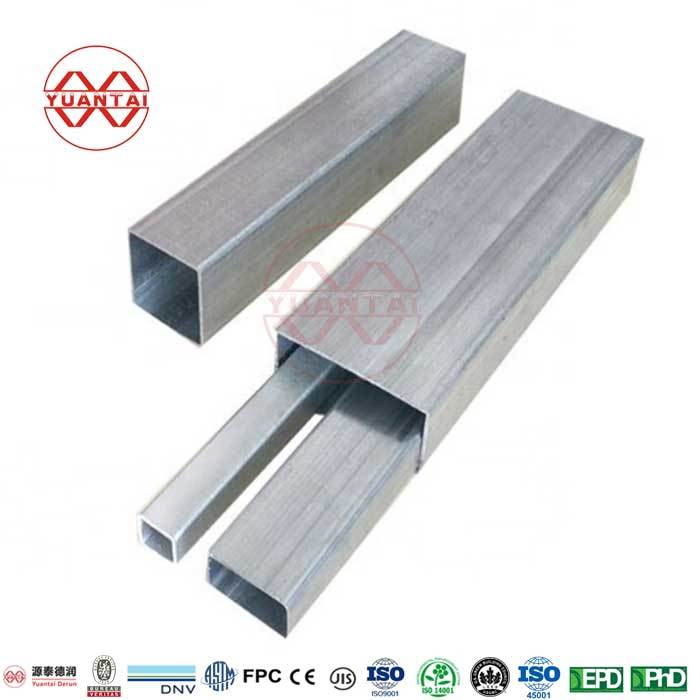

Overview of HSS Square Tube

HSS square tubes are hollow metal structures with a square cross-section. These tubes are commonly made from steel, providing them with remarkable structural integrity. Due to their geometric shape, they exhibit superior load-bearing capabilities compared to other structural profiles.

Advantages and Applications

12 factories, 72 production lines, 63 patented technologies, China's top 500 private enterprises and China's top 500 manufacturing industries, with an annual output of 5 million tons and a perennial spot supply of 200000 tons. China's largest square tube manufacturer.

YuantaiDerun's main products include square steel pipe, rectangular steel pipe, hot-dip galvanized steel pipe, ERW steel pipe, large-diameter thick wall square rectangular pipe, LSAW steel pipe, spiral steel pipe, seamless steel pipe, stainless steel pipe, galvanized coil, ppgi and stainless steel coil

Advantages of HSS Square Tubes

HSS square tubes bring several advantages to the table. Firstly, their inherent strength allows for the construction of lighter yet robust structures. Additionally, their hollow design provides excellent resistance to torsion and bending forces, making them ideal for dynamic applications. Furthermore, their aesthetic appeal and ease of fabrication make them a popular choice in architectural designs.

Excellent torsional resistance

Understanding Metal Tube Square

The Characteristics of Metal Tube Square

Metal tube square is a term used to describe various square-shaped metal tubes. These tubes can be made from different materials, such as steel, aluminum, or even copper. While each material offers its unique benefits, steel stands out for its exceptional strength and cost-effectiveness.

Advantages of Steel Square Tubes

Steel square tubes, in particular, offer several advantages. They provide excellent corrosion resistance, high durability, and are highly recyclable. Moreover, steel square tubes boast superior load-bearing capacities, making them suitable for demanding structural applications.

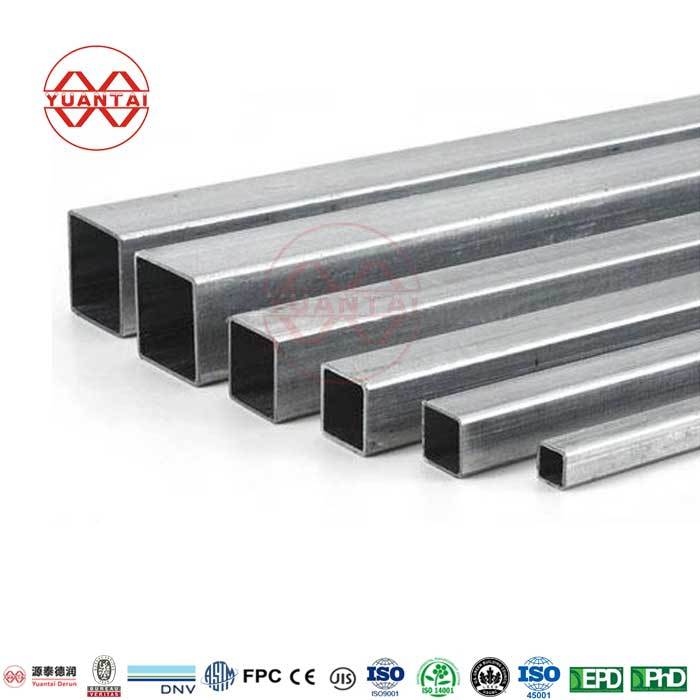

Importance of Square Tube Steel Size Chart

A square tube steel size chart is an essential tool for engineers, architects, and fabricators. It provides comprehensive dimensions and specifications for different sizes of square steel tubes. This chart enables accurate planning and design, ensuring precise fits and efficient material utilization.

The following are the size specifications for some square and rectangular pipes

O.D. mm | W.T.mm | O.D mm | W.T. mm | O.D mm | W.T. mm | O.D mm | W.T. mm |

20*20 | 1.3 | 60*120 80*100 90*90 | 1.50 | 180*180 | 3 | 300*800 400*700 550*550 500*600 | |

1.4 | 1.70 | 3.5-3.75 | 9.5-9.75 |

1.5 | 1.80 | 4.5-4.75 | 11.5-11.75 |

1.7 | 2.00 | 5.5-7.75 | 12-13.75 |

1.8 | 2.20 | 9.5-9.75 | 15-50 |

2.0 | 2.5-4.0 | 11.5-11.75 | |

20*30 25*25 | 1.3 | 4.25-4.75 | 12.0-25.0 | |

1.4 | 5.0-6.3 | 100*300 150*250 200*200 | 2.75 | 300*900 400*800 600*600 500*700 | |

1.5 | 7.5-8 | 3.0-4.0 | 9.5-9.75 |

1.7 | 50*150 60*140 80*120 100*100 | 1.50 | 4.5-9.75 | 11.5-11.75 |

1.8 | 1.70 | 11.5-11.75 | 12-13.75 |

2.0 | 2.00 | 12.5-12.75 | 15-50 |

2.2 | 2.20 | 13.5-13.75 | |

2.5-3.0 | 2.5-2.75 | 15.5-30 | |

20*40 25*40 30*30 30*40 | 1.3 | 3.0-4.75 | 150*300 200*250 | 3.75 | 300*1000 400*900 500*800 600*700 650*650 | |

1.4 | 5.5-6.3 | 4.5-4.75 | |

1.5 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 |

1.7 | 9.5-9.75 | 7.5-7.75 | 11.5-11.75 |

1.8 | 11.5-16 | 9.5-9.75 | 12-13.75 |

2.0 | 60*160 80*140 100*120 | 2.50 | 11.5-11.75 | 15-50 |

2.2 | 2.75 | 13.5-30 | |

2.5-3.0 | 3.0-4.75 | 200*300 250*250 | 3.75 | 400*1000 500*900 600*800 700*700 | |

3.25-4.0 | 5.5-6.3 | 4.5-4.75 | |

25*50 30*50 30*60 40*40 40*50 40*60 50*50 | 1.3 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 |

1.4 | 9.5-16 | 7.5-7.75 | 11.5-11.75 |

1.5 | 75*150 | 2.50 | 9.5-9.75 | 12-13.75 |

1.7 | 2.75 | 11.5-11.75 | 15-50 |

1.8 | 3.0-3.75 | 12-13.75 | |

2.0 | 4.5-4.75 | 15.5-30 | |

2.2 | 5.5-6.3 | 200*400 250*350 300*300 | 4.5-6.3 | 500*1000 600*900 700*800 750*750 | |

2.5-3.0 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 |

3.25-4.0 | 9.5-16 | 9.5-9.75 | 11.5-11.75 |

4.25-4.75 | 80*160 120*120 | 2.50 | 11.5-11.75 | 12-13.75 |

5.0-5.75 | 2.75 | 12-13.75 | 15-50 |

5.75-6.3 | 3.0-4.75 | 15.5-30 | |

40*80 50*70 50*80 60*60 | 1.3 | 5.5-6.3 | 200*500 250*450 300*400 350*350 | 5.5-6.3 | 500*1100 600*900 700*800 800*800 | |

1.5 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 |

1.7 | 9.5-9.75 | 9.5-9.75 | 11.5-11.75 |

1.8 | 11.5-20 | 11.5-11.75 | 12-13.75 |

2.0 | 100*150 | 2.50 | 12-13.75 | 15-50 |

2.2 | 2.75 | 15.5-30 | |

2.5-3.0 | 3.0-4.75 | 280*280 | 5.5-6.3 | 600*1100 700*1000 800*900 850*850 | |

3.25-4.0 | 5.5-6.3 | 7.5-7.75 | 9.5-9.75 |

4.25-4.75 | 7.5-7.75 | 9.5-9.75 | 11.5-11.75 |

5.0-6.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 |

40*100 60*80 70*70 | 1.3 | 11.5-20 | 12-13.75 | 15-50 |

1.5 | 100*200 120*180 150*150 | 2.50 | 15.5-30 | |

1.7 | 2.75 | 350*400 300*450 | 7.5-7.75 | 700*1100 800*1000 900*900 | |

1.8 | 3.0-7.75 | 9.5-9.75 | 11.5-11.75 |

2.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 |

2.2 | 11.5-20 | 12-13.75 | 15-50 |

2.5-3.0 | 100*250 150*200 | 3.00 | 15.5-30 | |

3.25-4.0 | 3.25-3.75 | 200*600 300*500 400*400 | 7.5-7.75 | 800*1100 900*1000 950*950 | |

4.25-4.75 | 4.25-4.75 | 9.5-9.75 | 11.5-11.75 |

5.0-6.3 | 9.5-9.75 | 11.5-11.75 | 12-13.75 |

50*100 60*90 60*100 75*75 80*80 | 1.3 | 11.5-11.75 | 12-13.75 | 15-50 |

1.5 | 12.25 | 15.5-40 | |

1.7 | 140*140 | 3.0-3.75 | 300*600 400*500 450*450 | 7.5-7.75 | 900*1100 1000*1000 800*1200 | |

1.8 | 4.5-6.3 | 9.5-9.75 | |

2.0 | 7.5-7.75 | 11.5-11.75 | 20-60 |

2.2 | 9.5-9.75 | 12-13.75 | |

2.5-3.0 | 11.5-25 | 15.5-40 | |

3.25-4.0 | 160*160 | 3.00 | 400*600 500*500 | 9.5-9.75 | 1100*1000 1200*1200 | |

4.25-4.75 | | 3.5-3.75 | 11.5-11.75 | 20-60 |

5.0-5.75 | | 4.25-7.75 | 12-13.75 | |

7.5-8 | | 9.5-25 | 15.5-40 | |

Applications of HSS Square Tubes

The applications of HSS square tubes span across multiple industries. They are widely used in construction projects, including the erection of buildings, bridges, and infrastructure. Additionally, these tubes find applications in the automotive, aerospace, renewable energy, and furniture industries, among others.

AIRPORT VENUES

Black high-frequency welded pipes are indispensable in airport venue buildings,Black high-frequency welded pipes are indispensable in the airport venue buildings. This is our cooperation project Beijing Daxing International Airport

EXPO VENUES

2020 Dubai World Expo venue,The 2020 Dubai World Expo venue is one of the projects we participate in

BRIDGE CONSTRUCTION

Hong Kong-Zhuhai-Macao Bridge,Our products are involved in the construction of bridges. It is a bridge and tunnel project connecting Hong Kong, Zhuhai, Guangdong and Macao in China.

BUILDING CONSTRUCTION

SINGAPORE GOOGLE BUILDING,From 2018 to 2019, we provided steel pipes with hollow section profiles for the construction of Google building in Singapore

GREENHOUSE CONSTRUCTION

From 2017 to 2018, we provided 75000 tons of steel pipe products for the green house of the million feidan land improvement project in Egypt.

CBD business district building

From 2019 to 2020, we provided our steel pipe products for the building development of CBD business district buildings in Cairo, Egypt

THEATER CONSTRUCTION

Located in the west of Tiananmen Square in central Beijing, the National Grand Theatre is the largest theater complex in Asia.

High grade villa building

In 2018, we provided steel pipe products for Dubai Hill high-end villa construction project

The Significance of Calculating Square Tube Steel Weight

Calculating the weight of square tube steel is crucial for engineering and construction purposes. It allows designers to determine the load capacity of structures, evaluate transportation requirements, and estimate material costs accurately.

Factors Affecting Square Tube Weight

The weight of a square tube steel is influenced by factors such as the dimensions of the tube, the thickness of the walls, and the type of steel used. In this section, we will explore these factors in detail and provide insights into how they affect the overall weight of square tubes.

Understanding Square Tube Weight Carrying Capacity

The weight carrying capacity of square tubes is a critical consideration in structural engineering. Several factors affect this capacity, including the material properties, tube dimensions, and the type of load applied. We will examine these factors and discuss how they impact the overall strength and performance of square tubes.

The Versatility of Steel Rectangular Tubes

Steel rectangular tubes, similar to square tubes, offer exceptional strength and versatility. In this section, we will explore the different sizes available, their applications, and the advantages they bring to various industries.

Determinants of Square Steel Pipe Price

The price of square steel pipes may vary due to various factors. This section will discuss these determining factors, including raw material costs, manufacturing processes, market demand, and other influencing factors. Understanding these aspects will provide valuable insights for buyers and suppliers in the steel industry. Please contact us immediately

Choosing the Appropriate Length

The length of a square steel pipe is an important consideration in construction projects. It affects installation ease, transportation logistics, and overall cost efficiency. This section will guide you in determining the optimal length based on different project requirements.

In conclusion, HSS square tubes have revolutionized the steel industry with their exceptional strength, versatility, and aesthetic appeal. Understanding the size charts, weight calculations, and carrying capacities play a crucial role in utilizing these tubes effectively. Additionally, comprehending the factors influencing pricing helps both buyers and sellers make informed decisions. With their wide range of applications and benefits, square steel tubes continue to shape the world around us.

Q1: Are HSS square tubes only made from steel?

A: While steel is the most common material used for HSS square tubes, they can also be manufactured using other metals such as aluminum or copper.

Q2: What are the advantages of using square steel tubes in furniture design?

A: Square steel tubes offer exceptional strength and durability, making them ideal for furniture design that requires both aesthetics and structural integrity.

Q3: Can square steel tubes be used in corrosive environments?

A: Yes, square steel tubes can be coated or galvanized to enhance their corrosion resistance, making them suitable for use in corrosive environments.

Q4: What are the size limitations of square steel tubes?

A: The size limitations of square steel tubes depend on various factors, including manufacturing capabilities and transportation logistics. However, they are available in a wide range of sizes to cater to different applications.

Q5: How can I determine the weight carrying capacity of a square steel tube?

A: The weight carrying capacity of a square steel tube depends on its dimensions, material properties, and the type of load applied. Consulting relevant engineering specifications or conducting load tests can provide accurate information.