- Home

- About us

- Products

- square steel pipe

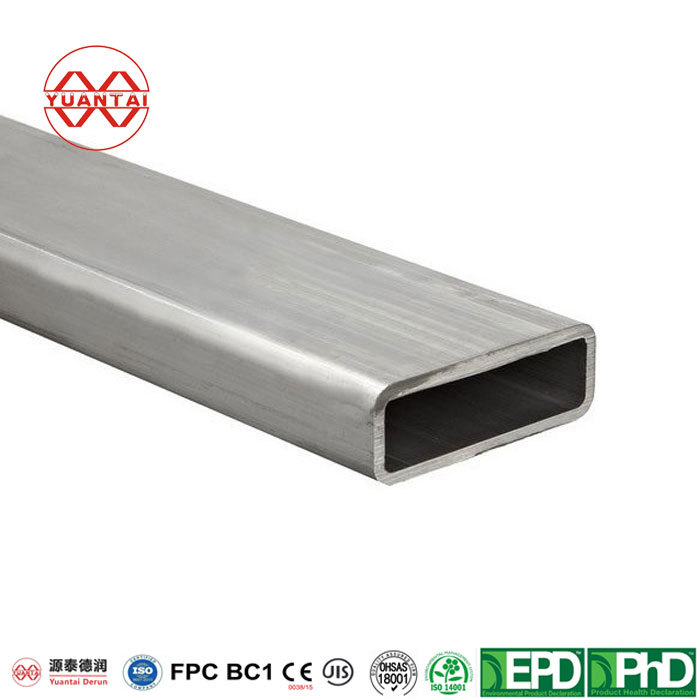

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

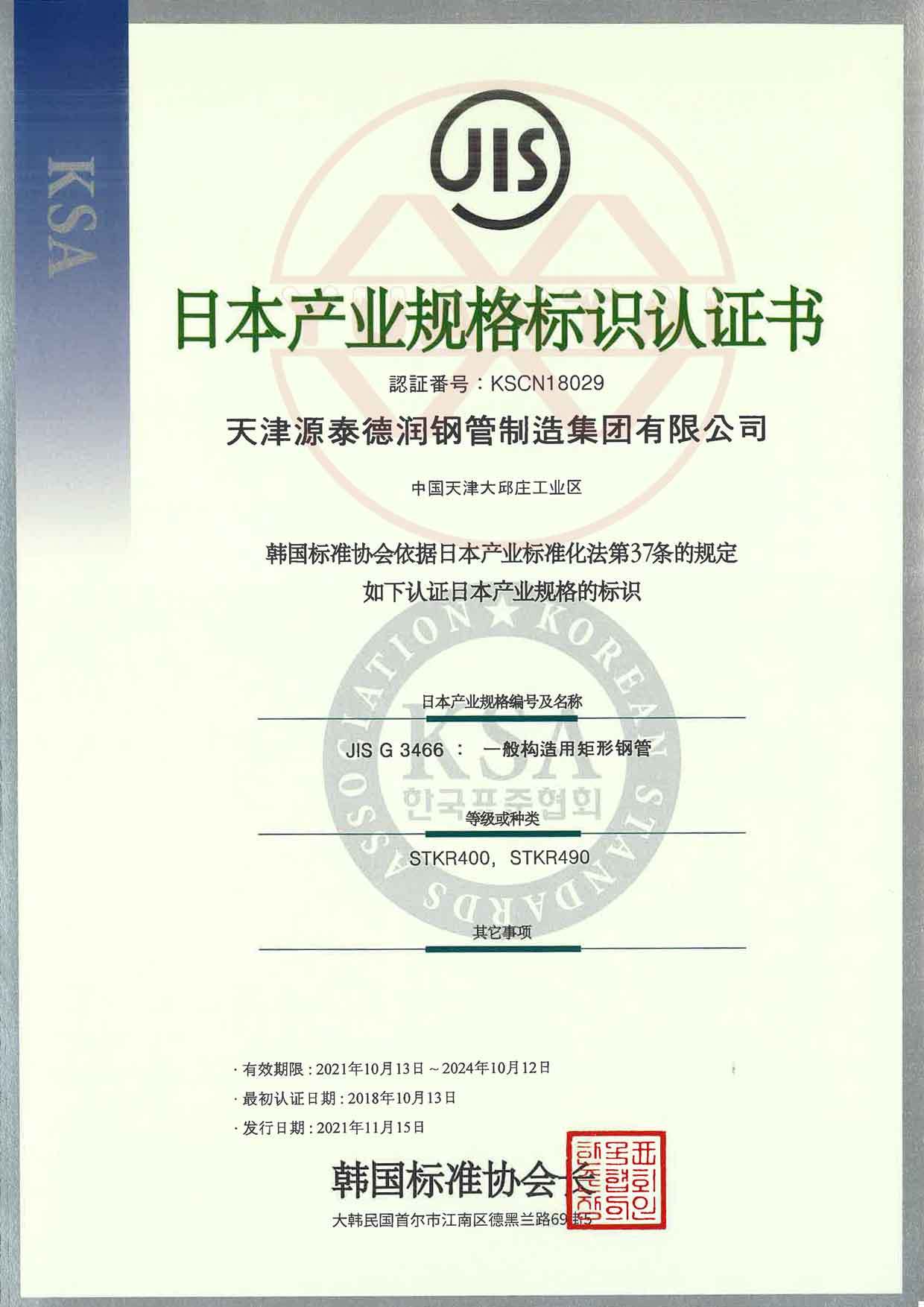

- Certificate

- Contact us

hot dip galvanized pipe factory direct supply Tianjin YuantaiDerun

- group name

- Hot Dipped Galvanized Steel Pipe

- Min Order

- 25 ton

- brand name

- Yuantai Derun Steel Pipe Manufacturing Group

- model

- hfw-yt-275

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Sun, 21 Dec 2025 20:46:31 GMT

Paramtents

Thickness 0.5- 60 mm

OD(outer diameter) 10.3mm-3620mm

Supply capacity Annual output of 5 million tons

Certification CE,LEED,BV,PHD&EPD,BC1,EN10210/10219,ISO

Surface Treatment REQUEST

Tolerance as required

Brand YUANTAI DERUN

Length 0.5-24M according to client requirement

Standards ASTM A500/A501,EN10219/10210,JIS G3466,AS1163

Materials Gr.A/B/C,S275J0H,S355JR,S355J0H,S355J2H,A36,

Packaging Customers't Requirement

Packging & Delivery

-

Min Order25 ton

Briefing

YuantaiDerun produce many kind of hot dip galvanized pipes, factory direct supply,fast delivery,low cost,high quality.

Detailed

hot dip galvanized pipe |factory direct supply |Tianjin |YuantaiDerun

1.What's hot dip galvanized pipe?

In order to improve the corrosion resistance of Hot-dip galvanization steel pipes, general steel pipes are galvanized. Hot-dip galvanization steel pipe is formed by immersing the black pipe into the heated zinc bath, repeating several times, and finally taking out the steel pipe. The Hot-dip galvanization steel pipe has a thick hot-dip galvanized coating, strong anti-corrosion ability, and a rough surface. However, the service life of the steel pipe will be longer and the cost will be higher than that of ordinary galvanized steel pipe.

2. Hot-dip galvanized pipes price

Yuantai Derun is a direct wholesale manufacturer, so the price of hot-dip galvanized steel pipes is relatively low. Welcome to purchase. In addition to the low price, the quality of Yuantai's hot-dip galvanized steel pipes is also very reliable, with sufficient stock, complete specifications, and large production capacity, which can meet your one-stop procurement needs for hot-dip galvanized steel pipes. Contact Us Now!

3.Hot-dip galvanized pipes ADVANTAGES AND FEATURES

Steel pipe orifice leveling

Yuantaiderun steel pipe orifice is very flat,Tight weld

The hot dip galvanized steel pipe surface is smooth

The surface of the steel pipe shall be smooth without burrs

No joint, no cushion bar

There is no joint and backing bar in the finished steel pipe

Source of raw materials

Large factory direct supply

Each steel pipe 100% complies with international standards

Each steel pipe is inspected layer by layer

OEM&ODM&OBM

Yuantaiderun accepts OEM,ODM,OBM

4. Hot dip galvanized steel pipe load-bearing

Galvanized steel pipes can withstand around 20 kilograms. Generally speaking, it is 6 meters long, but some are also determined by the customer based on the rolling length, which is not easy to calculate without thickness. Formula: 0.02466 * wall thickness * (outer diameter wall thickness) Hot dip galvanized pipe is used to produce an alloy layer by reacting the molten metal with the iron substrate, thereby combining the substrate and coating. Hot dip galvanizing refers to the pickling of steel pipes first. In order to remove iron oxide on the surface of steel pipes, after pickling, the steel pipes are cleaned in ammonium chloride or Zinc chloride aqueous solution or mixed ammonium chloride and Zinc chloride aqueous solution tank, and then sent to the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion, and long service life. The substrate of hot-dip galvanized steel pipes undergoes complex physical and chemical reactions with the molten plating solution, forming a corrosion-resistant and tightly structured zinc iron alloy layer. The alloy layer is integrated with the pure zinc layer and the steel pipe substrate, so its corrosion resistance is strong.

Generally, the bearing pressure of Water gas transmission pipe is 1.6MPa, and the bearing pressure of seamless steel pipe is 2.0MPa. The pressure of steel pipe varies with the thickness of steel pipe. The bearing pressure of galvanized seamless pipe and galvanized straight seam pipe shall refer to the original pipe technical standards! Fire protection pipelines generally have a pressure of 6 kilograms, but there are few special requirements for 8 kilograms and 16 kilograms. GB straight seam welded steel pipe (which is the type that is measured in inches, some are galvanized pipes), usually with a maximum pressure of 10 kilograms. According to me, I forgot (please refer to the large hardware manual). Buried fire pipelines are generally seamless

5.Executive standards for hot-dip galvanized steel pipes

The execution standards for hot-dip galvanized steel pipes are mainly divided into two categories,

One type is international standards,

One type is domestic standards. The specific standards are as follows:

1. International standards:

STM 53/53M-20: A standard issued by the STM International Standards Committee in the United States, which specifies the requirements for black and hot-dip galvanized welded and seamless steel pipes used for conveying liquids and gases.

BS1387: A standard issued by the British Standards Institution that specifies the requirements for hot-dip galvanized welded and seamless steel pipes.

2. Domestic standards:

GB/T3091-2015: Welded steel pipes for low-pressure fluid transportation.

GB/T13793-2008: Straight seam welded steel pipes.

GB/T21835-2008: Dimensions and unit length weight of welded steel pipes.

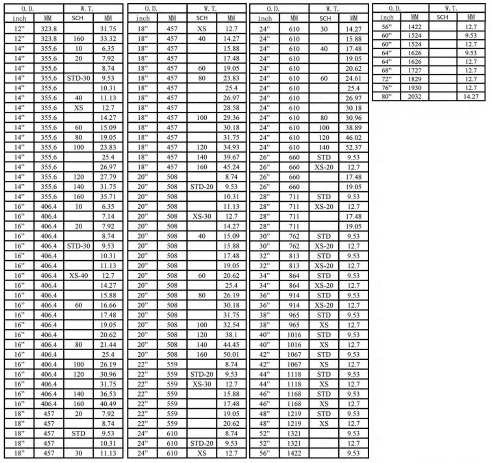

6. Hot dip galvanized steel pipe specification table

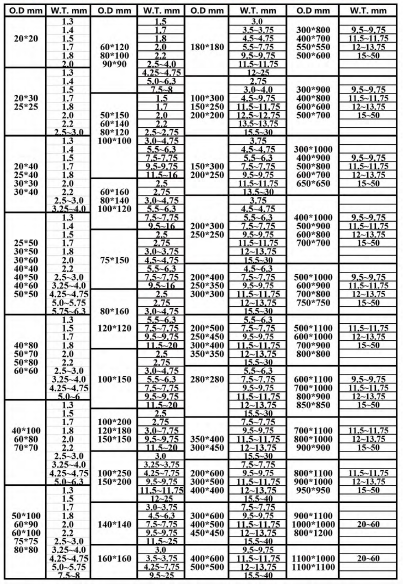

hot dip galvanized square rectangular steel tube specification table

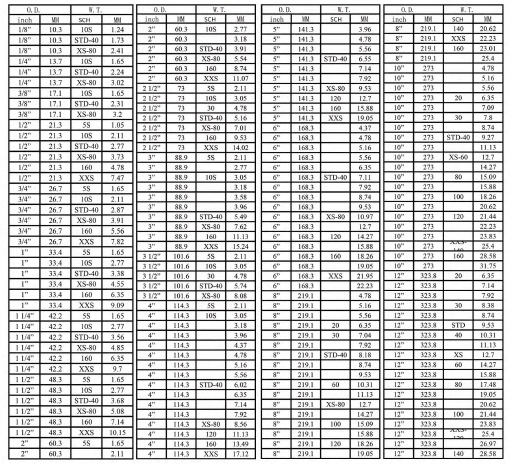

hot dip galvanized round steel tube specification table

7.Production process of Hot-dip galvanization steel pipe

The process flow is: black pipe - alkali washing - water washing - acid washing - clean water rinsing - dipping agent - drying - Hot-dip galvanization - external blowing - internal blowing - air cooling - water cooling - passivation - water rinsing - inspection - weighing - warehousing.

8.One Corner of Yuantai derun workshop (Top 3 in China)hot dip galvanized pipe manufacturers

Consistent persistence

Achieved a category and individual champion

Time can change everything

Time may not change everything, such as the initial heart

In workshop of yuantaiderun

The weaker sex is no inferior to the male.

In all posts of Yuantai

everyone is working hard

Steel pipe forming unit

We have 72 big guys like this

Clean and tidy warehouse

Ensure that each customer's products can be delivered quickly

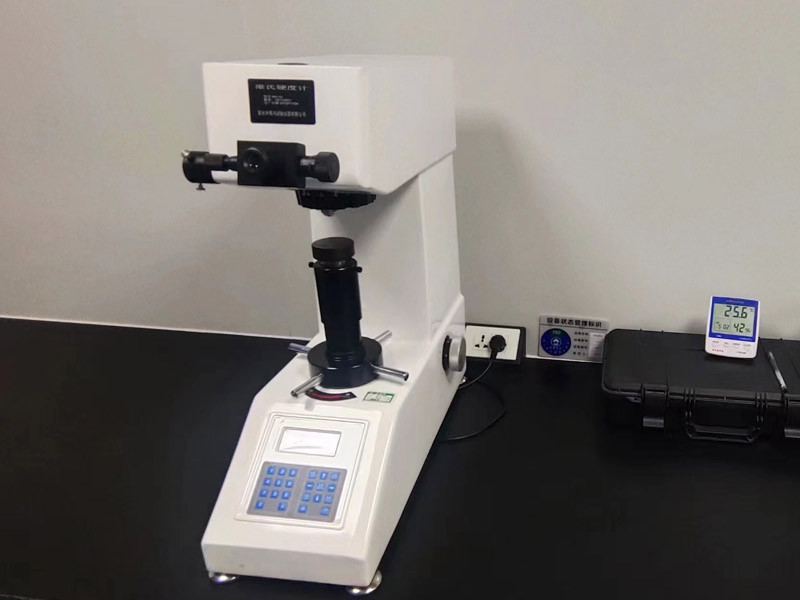

9.Strict product inspection of Hot-dip galvanization steel pipe

Each steel pipe must pass the inspection layer by layer. Only the products that pass the inspection can leave the factory. Never let an unqualified product flow into the market

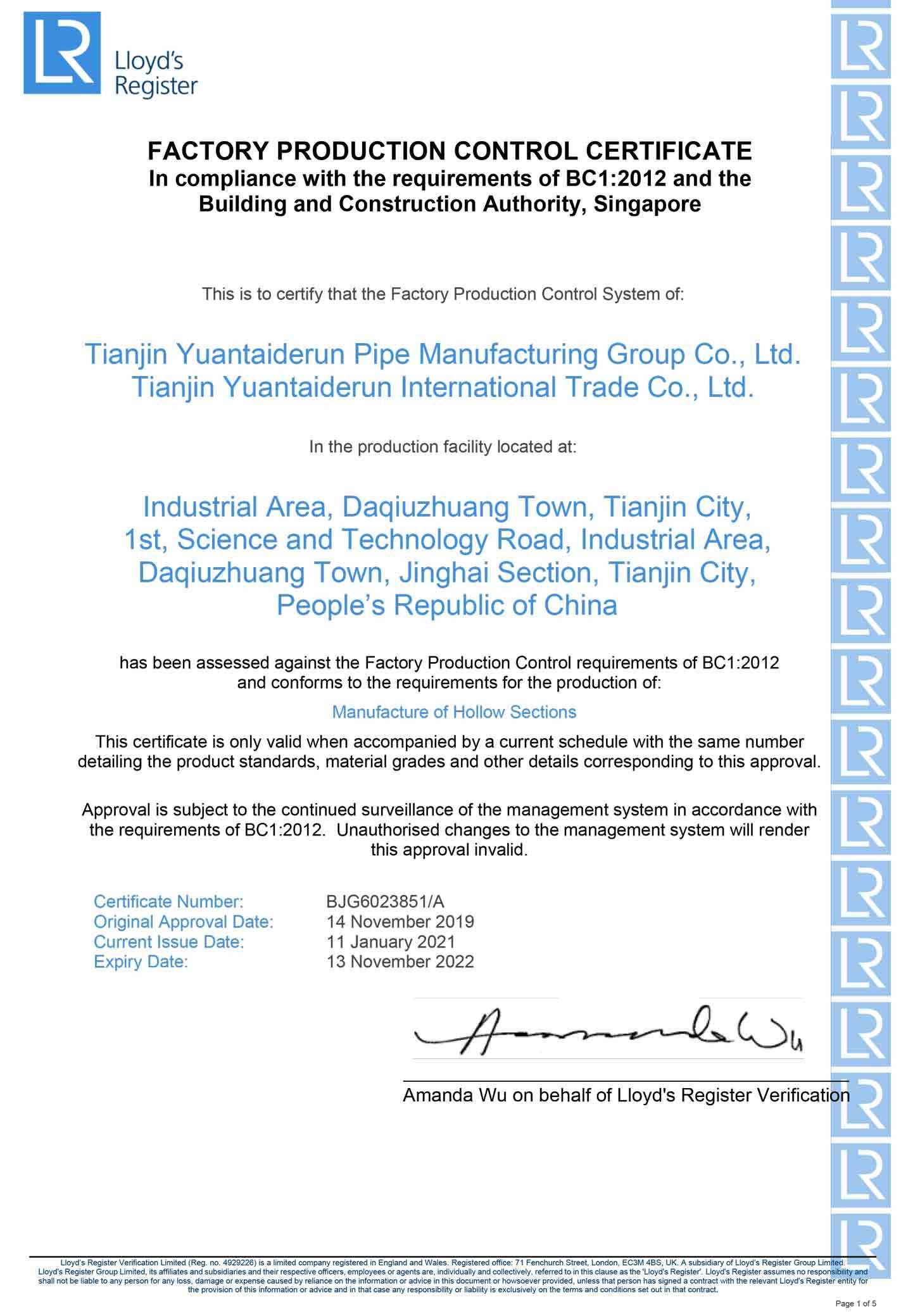

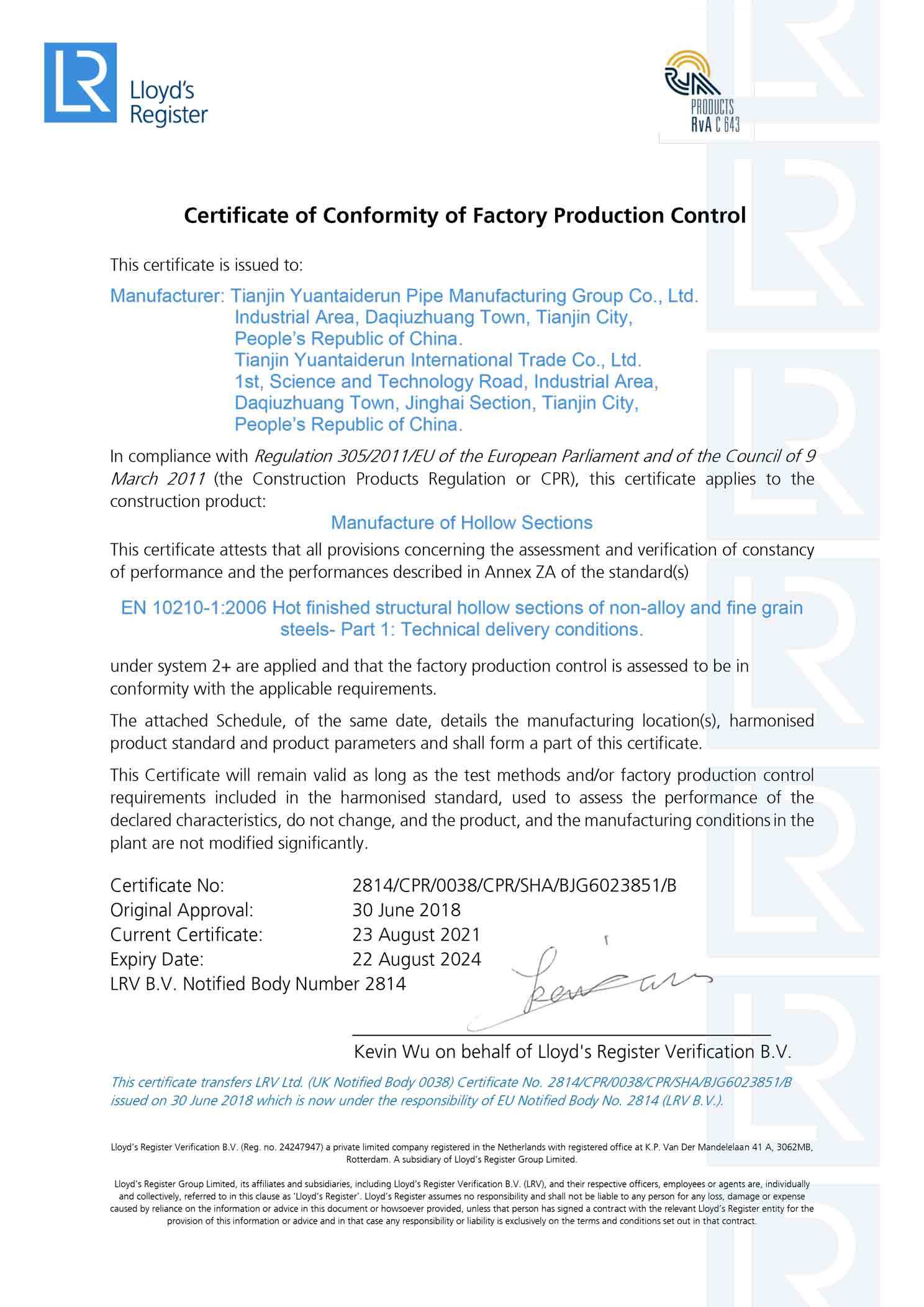

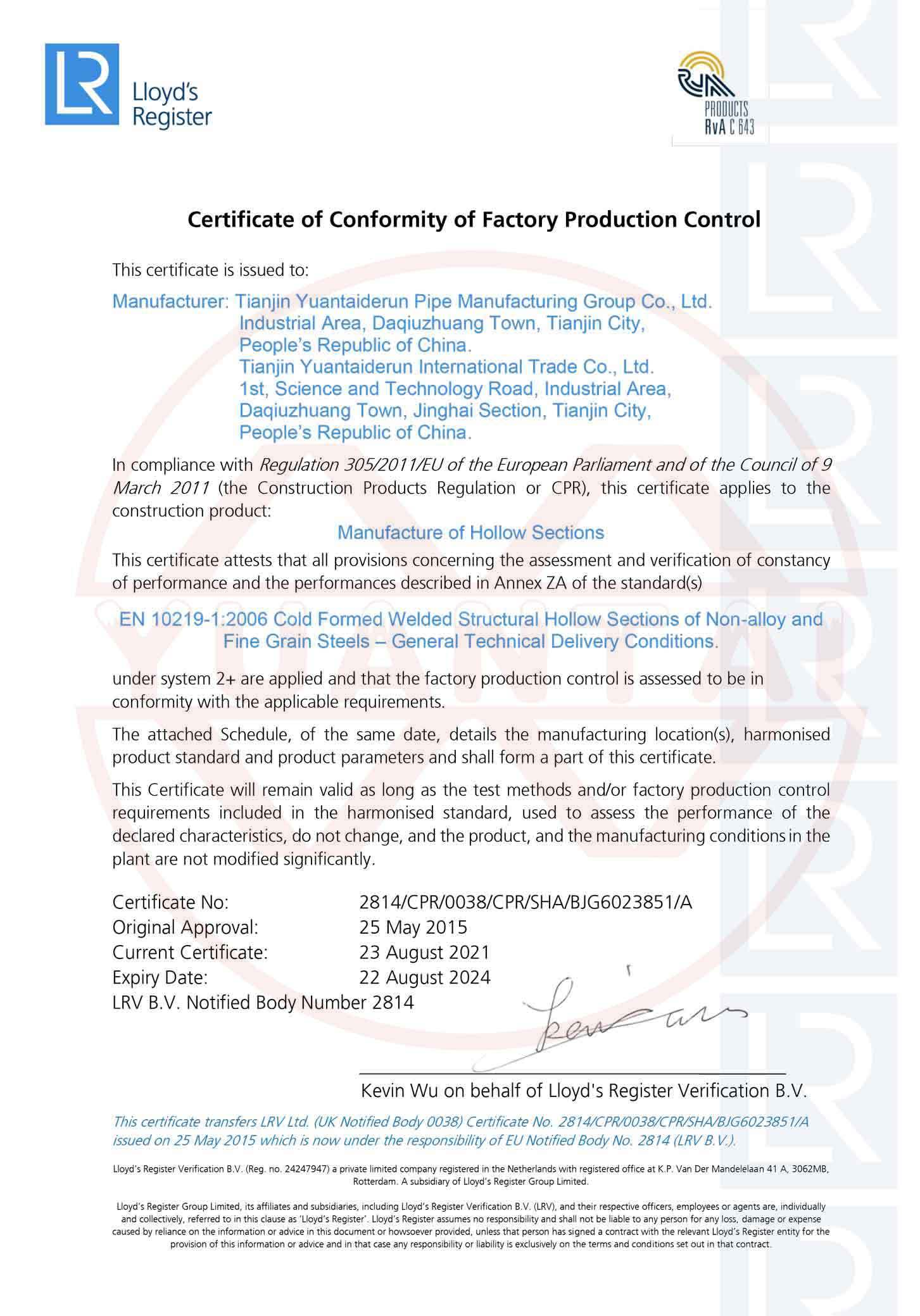

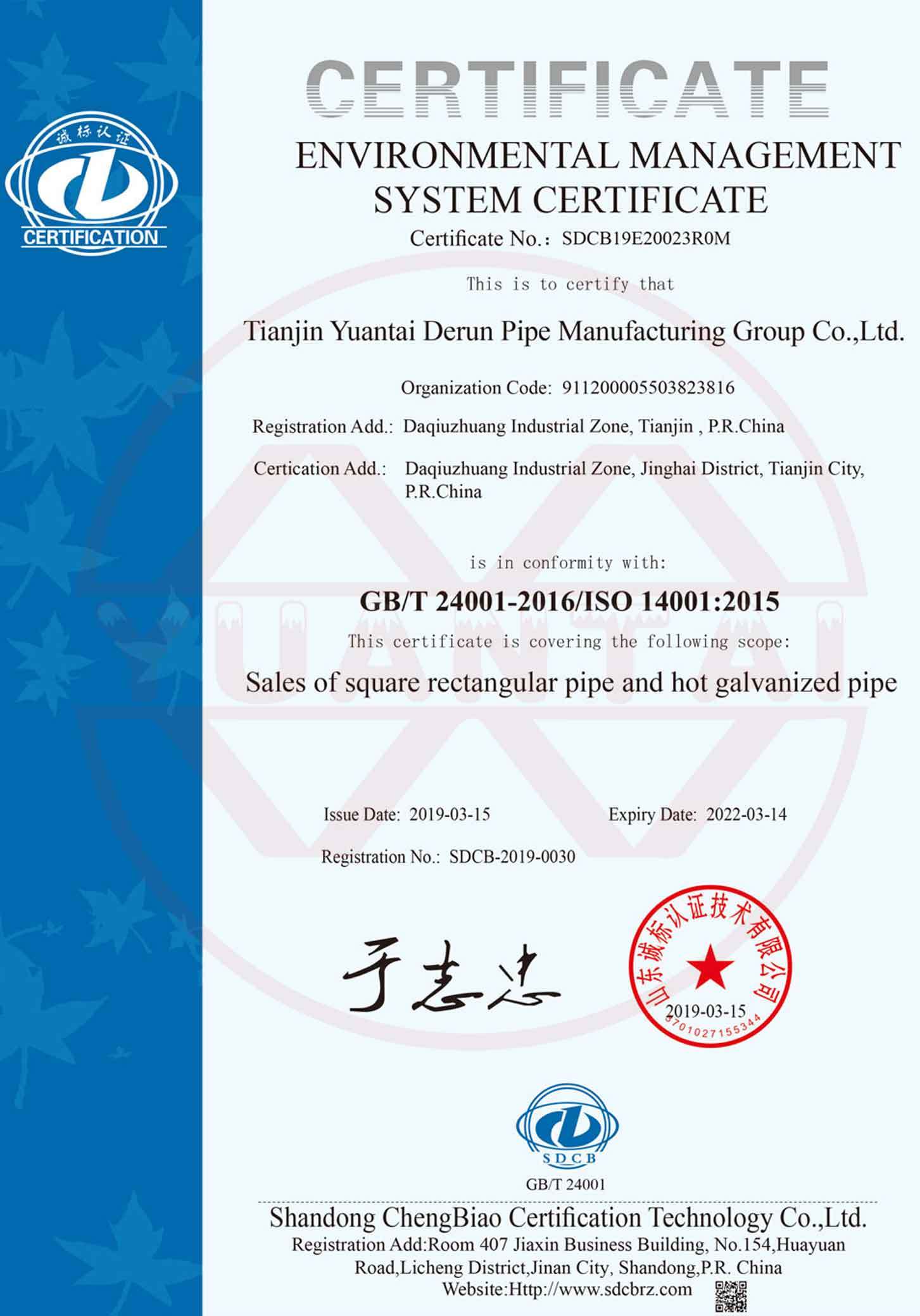

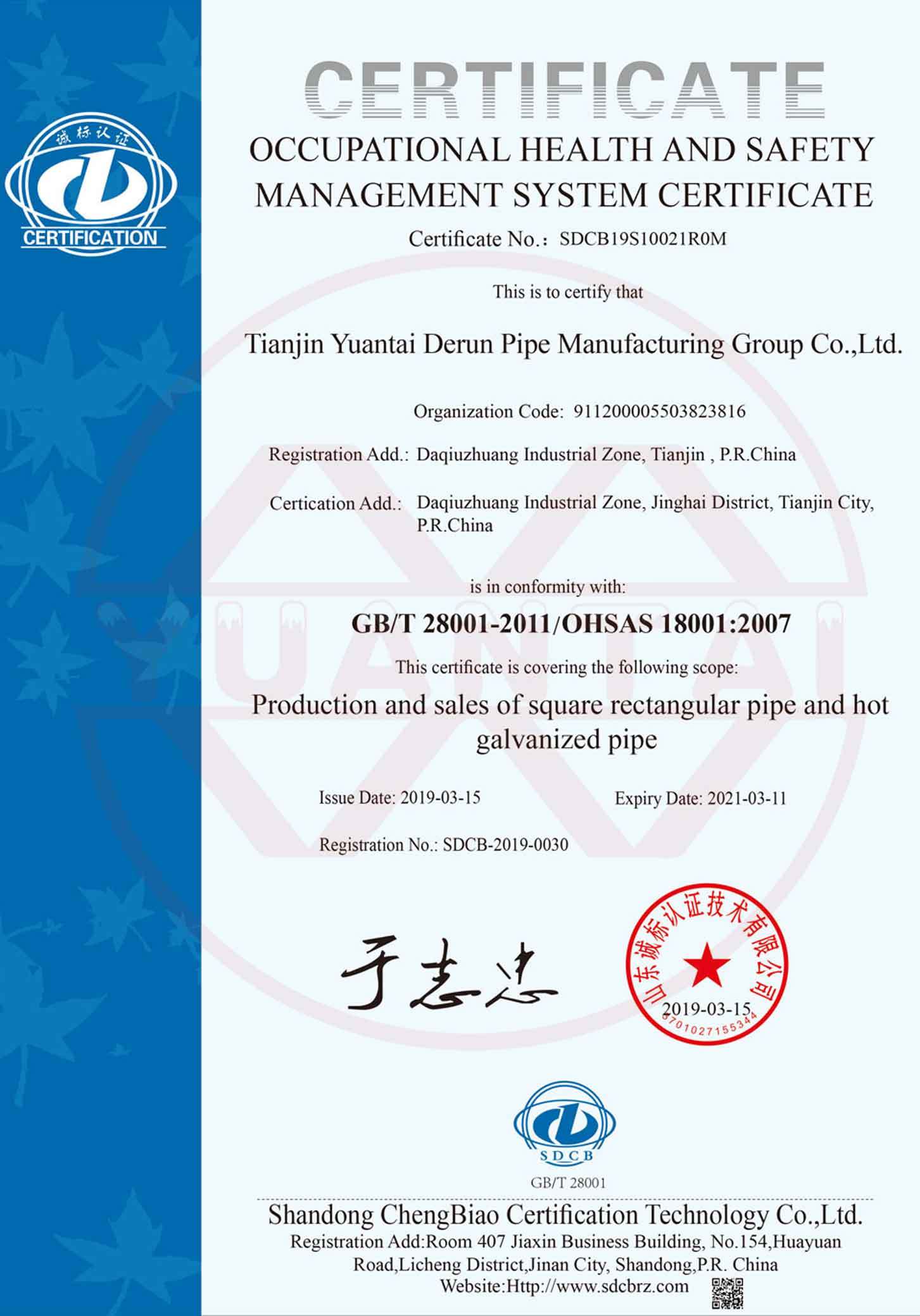

10.Hot dip galvanized pipe Certificate

BC1

FACTORY PRODUCTION CONTROL CERTIFICATE,ln compliance with the requirements of BC1:2012 and the Building and Construction Authority, Singapore

EN10210

Manufacture of Hollow Sections :This certificate proves that the performance stability meets the performance of European standards

EN10219

Manufacture of Hollow Sections :This certificate proves that the performance stability meets the performance of European standards

BV

This certficate is issued to attest that Bureau Vveritas Marine & Ofishore has perormed, at the above company's request and in compliance withthe requirements of NR320,a satisfactory assessment of the manudacturing facilities and associated quality procedures related to the ranrge of therecogniition.

ISO14001(GB/T 24001)

ENVIRONMENTAL MANAGEMENT SYSTEM CERTIFICATE

OHSAS 18001(GB/T28001-2011)

OCCUPATIONAL HEALTH AND SAFETYMANAGEMENT SYSTEM CERTIFICATE

ISO9001(GB/T19001)

The production of rectangular pipe and hot-dip galvanized pipe, the sales and service of metal materials, and the quality management system meet the requirements

GB / t19001-2016 / iso9001:2015

JIS G3466

Jis G 3466 : Carbon steel square and rectangular tubes for general structure meet JIS G3466 standard