- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

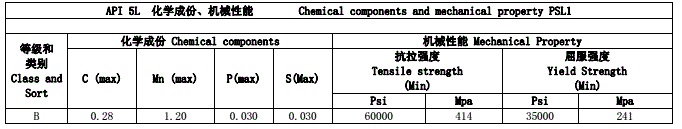

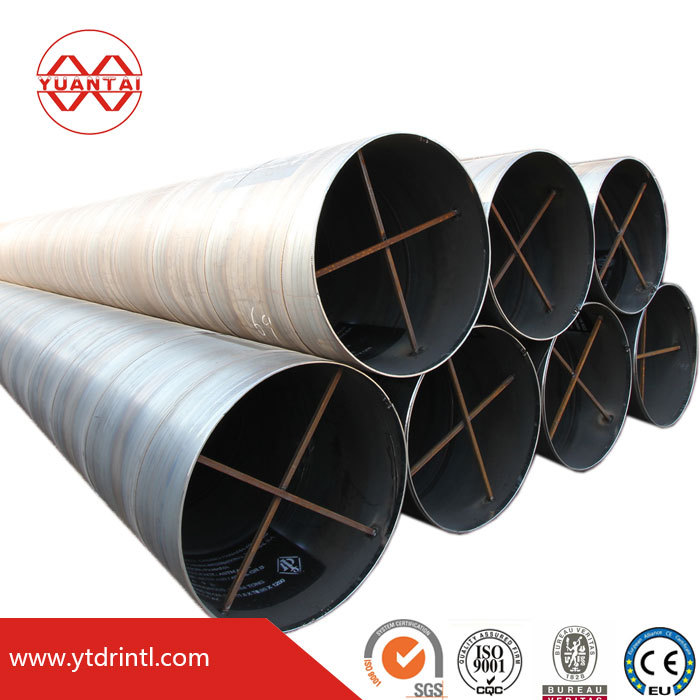

API 5L PSL1 GRB spiral steel pipe wholesale factory Horizontal drilling protection pipe

- group name

- spiral steel pipe

- Min Order

- 30 ton

- brand name

- Yuantai Derun Steel Pipe Manufacturing Group

- model

- ytdr-API 5L PSL1 GRB

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Sun, 21 Dec 2025 17:20:38 GMT

Paramtents

Standard API 5L, ASTM A501/500, bs,EN10210/10219,JIS G3466

Thickness 4mm to 30mm

Outer Diameter(OD) 219mm to 2032mm

Supply capacity Annual output of 5 million tons

Certification API/SGS/BV/JIS/EN/ISO/CE/BC1/GB/EPD&PHD/LEED

Alloy Or Not Non-Alloy

Length 3mm-24meters or as client required

Packing Loosed PCS/nylon rope(for the coating pipes)

Supply Ability 500000 Metric Ton/Metric Tons per Year

Delivery Time 7-30 Days

Grade GRB

Brand YuantaiDerun

Packging & Delivery

-

Min Order30 ton

Briefing

Discover the power of our API 5L PSL1 GRB spiral steel pipe - the ultimate solution for horizontal drilling protection.

Detailed

API 5L PSL1 GRB spiral steel pipe wholesale factory Horizontal drilling protection pipe

Over view

API 5L generally refers to the execution standard for pipeline steel pipes, which are used to transport oil, steam, water, etc. extracted from the ground to pipelines in oil and natural gas industry enterprises. Pipeline steel pipes include two categories: seamless steel pipes and welded steel pipes. Currently, the commonly used welded steel pipe types in oil pipelines in China include spiral submerged arc welded pipes (SSAW), straight seam submerged arc welded pipes (LSAW), resistance welded pipes (ERW), and seamless steel pipes. Spiral welded pipe is the main type of pipe material purchased for API 5L pipeline pipes.

Different point between API 5L PSL1 and API 5L PSL2

When it comes to API 5L, everyone knows that there are two standards under it, PSL1 and PSL2. Although there is only a word difference, the content of these two standards is vastly different. This is similar to the GB/T9711.1.2.3 standard, which all mention the same component, but the requirements are thousands of miles apart. Below, I will elaborate on the differences between PSL1 and PSL2:

1. PSL is the abbreviation for product specification level. The product specification level of pipeline pipes is divided into PSL1 and PSL2, and it can also be said that the quality level is divided into PSL1 and PSL2. PSL2 is higher than PSL1, and these two specification levels are not only different in terms of inspection requirements, but also in terms of chemical composition and mechanical properties. Therefore, when ordering according to API 5L, the terms in the contract must indicate not only the usual indicators such as specifications and steel grades, but also the product specification level, that is, PSL1 or PSL2. PSL2 is stricter than PSL1 in terms of chemical composition, tensile properties, impact energy, non-destructive testing, and other indicators.

2. PSL1 does not require impact performance. For all steel grades except x80, the average value of full size 0 ℃ Akv for PSL2 is ≥ 41J in the longitudinal direction and ≥ 27J in the transverse direction. X80 steel grade, full size 0 ℃ Akv average value: longitudinal ≥ 101J, transverse ≥ 68J.

3. Pipeline pipes should be subjected to water pressure testing one by one, and the standard does not specify that non-destructive water pressure testing is allowed, which is also a significant difference between API standards and Chinese standards. PSL1 does not require non-destructive testing, PSL2 should undergo non-destructive testing one by one.

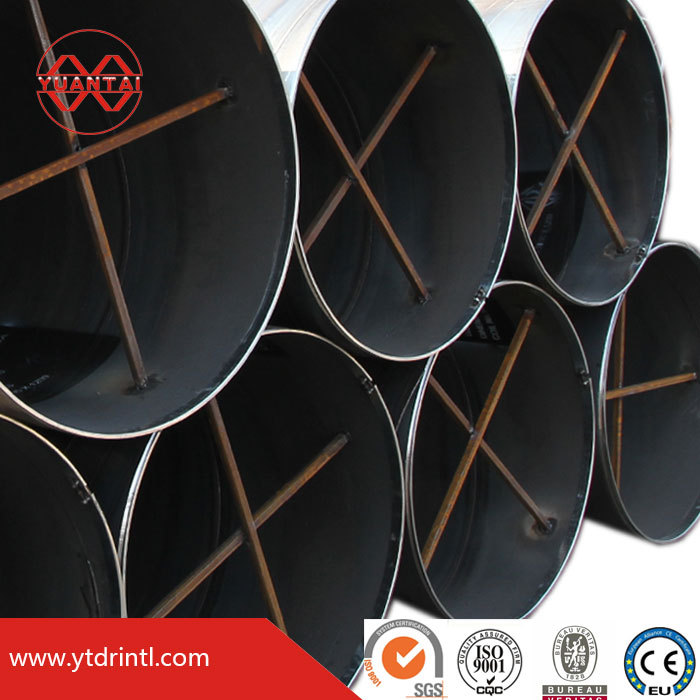

API 5L PSL1 spiral steel pipe chemical composition and mechanical property

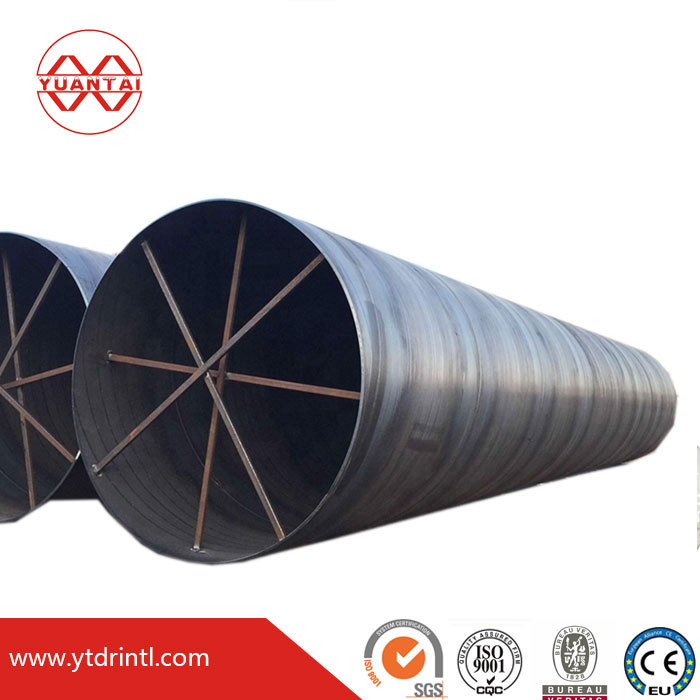

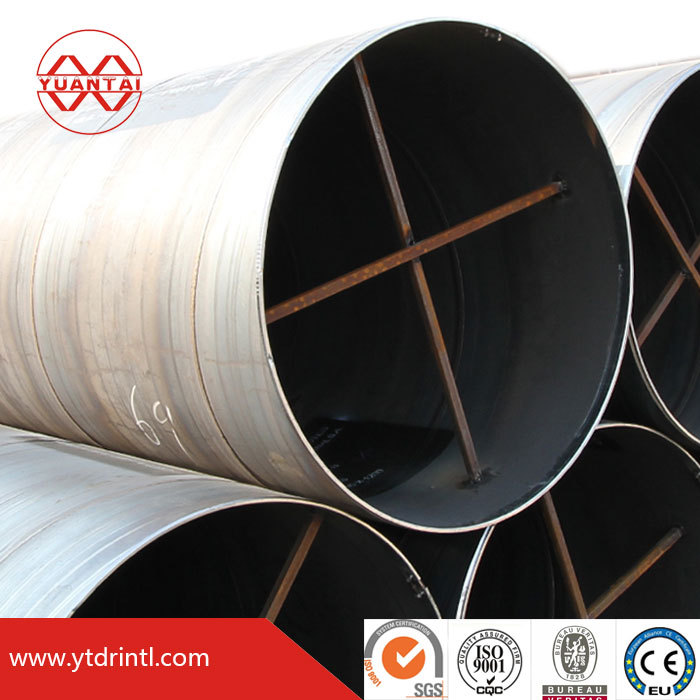

Product detail of API 5L PSL1 spiral steel pipe

one Corner of workshop

In Yuantai's workshop

Women are no inferior to men.

Consistent adherence

Achieved a category single champion

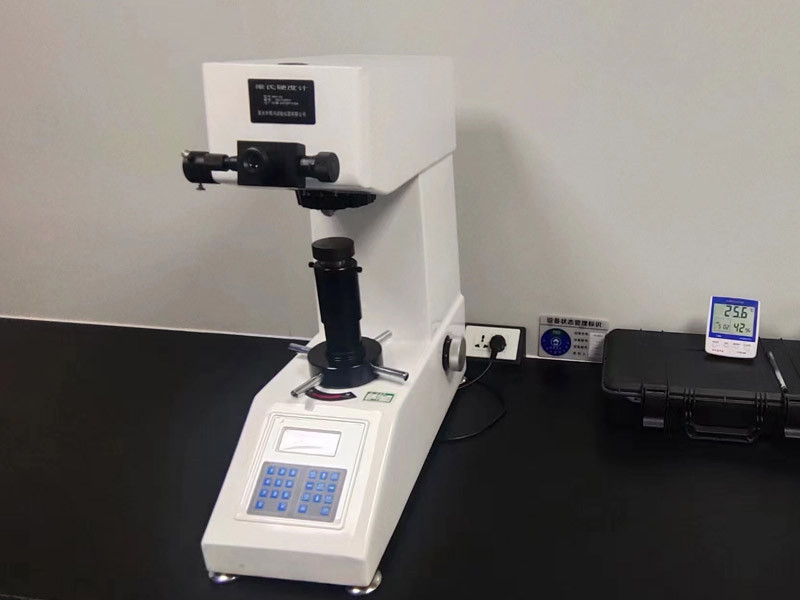

Strict layer by layer inspection

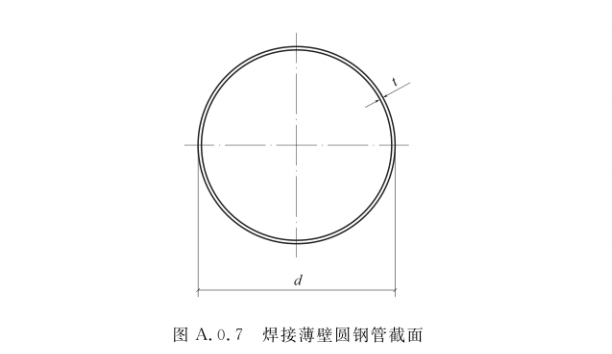

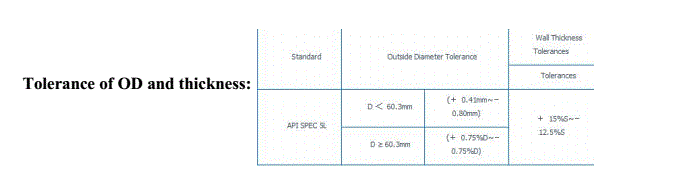

API 5L PSL1 spiral steel pipe Dimensional tolerance

Certificate