- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

Polypropylene 3PP anti-corrosion spiral welded steel pipe

- group name

- spiral steel pipe

- Min Order

- 2 ton

- brand name

- Yuantai Derun Steel Pipe Manufacturing Group

- model

- 3PP coating steel pipe

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Sun, 21 Dec 2025 17:27:00 GMT

Paramtents

Standard API 5L, ASTM A501/500, bs,EN10210/10219,JIS G3466

Thickness 4mm to 30mm

Outer Diameter(OD) 219mm to 2032mm

Certification API/SGS/BV/JIS/EN/ISO/CE/BC1/GB/EPD&PHD/LEED

Alloy Or Not Non-Alloy

Length 1-24meters or as client required

Packing Loosed PCS/nylon rope(for the coating pipes)

Supply Ability 500000 Metric Ton/Metric Tons per Year

Delivery Time 7-30 Days

Grade Gr.A,Gr.B,Gr.C,S275J0H,S355JR,S355J0H,S355J2H,Q195

Packging & Delivery

-

Min Order2 ton

Briefing

Yuantaiderun group can provide various specifications of Polypropylene 3PP anti-corrosion spiral welded steel pipe

Detailed

Polypropylene 3PP Anti-Corrosion Spiral Welded Steel Pipe

Polypropylene 3PP anti-corrosion spiral steel pipe is a spiral welded steel pipe with three types of anti-corrosion coatings, also known as 3PP steel pipe. At present, the polypropylene 3PP anti-corrosion spiral steel pipes supplied by Yuantai Derun are produced according to the German standard DIN30678. The main advantages are strong anti-corrosion ability and high temperature resistance. Often used in pipeline systems in desert areas.

Coating Structure

Polypropylene 3PP Anti-Corrosion Spiral Welded Steel Pipe have 3 coating layer,3PP anti-corrosion refers to the three-layer PP anti-corrosion structure of pipelines:

The first layer of epoxy powder (FBE),

Second layer adhesive (AD),

The third layer of polyethylene (PP).

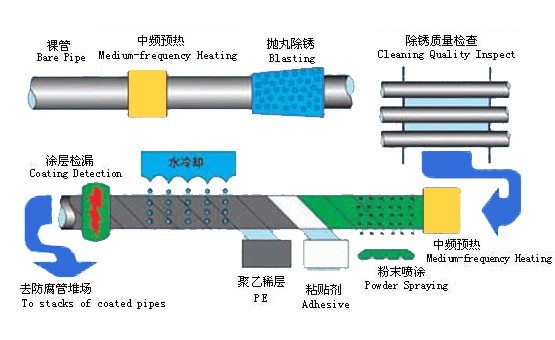

3PP Spiral Steel Pipes Making Process

3PP Spiral Steel Pipes Making Process mainly including those steps:

bare spiral welded steel pipe->Intermediate frequency preheating->Shot blasting rust removal->Rust removal quality inspection->Intermediate frequency preheating->Powder coating->Adhesive->Polyethylene layer->water cooling->Coating inspection->3PP anti-corrosion pipe storage

3PP Spiral Steel Pipes Making Process mainly including those steps:

bare spiral welded steel pipe->Intermediate frequency preheating->Shot blasting rust removal->Rust removal quality inspection->Intermediate frequency preheating->Powder coating->Adhesive->Polyethylene layer->water cooling->Coating inspection->3PP anti-corrosion pipe storage

Application Of 3PP Steel Pipe

3PP steel pipe is mainly used for those industries.3PP coated spiral welded pipes are mainly used for transporting high-temperature media and for pipeline laying in desert areas with high surface temperatures and long sunshine hours. Therefore, they have been increasingly widely used in buried water, gas, and oil pipelines in areas with high surface temperatures and long sunshine hours.