- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

PPGI roofing sheet

- group name

- PPGI coil

- Min Order

- 5 ton

- brand name

- Yuantai Derun Steel Pipe Manufacturing Group

- model

- Wave Steel Plate/sheet

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Tue, 03 Sep 2024 15:16:14 GMT

Paramtents

Color customization

Standard AiSi, ASTM, bs, GB, JIS, EN,AS ETC

Technique Cold Rolled

Tolerance Requirement

Packging & Delivery

-

Min Order5 ton

Briefing

China ppgi roofing sheet wholesale factory(OEM ODM OBM)yuantaiderun complete specifications with high quality and low price

Detailed

PPGI Roofing Sheet For Building Materials

PPGI roofing sheet for building materials is a very common type of metal building sheet. It is usually made by covering a substrate such as galvanized sheet with colored coating. The advantages are strong anti-corrosion ability, beautiful appearance, easy processing, and affordable price. Yuantai Derun is china ppgi roofing sheet supplier.

Flexibly Customize Your PPGI Roof Sheet

At Yuantai Derun, you can flexibly customize your PPGI Roof Sheet with customization options including color, pattern, whether the surface has a thin film, gloss type (high gloss, matte), coating thickness, galvanized layer thickness, substrate thickness, width, length, and more. Send your customization request immediately.

Color Customization

Pattern Customization

Film Covering

Gloss Type

Fast PPGI Roofing Sheet Quotes For You

No matter how the market for color coated rolls changes,The Yuantai Derun team can provide you with fast PPGI roofing sheet quetes. Send an inquiry immediately.

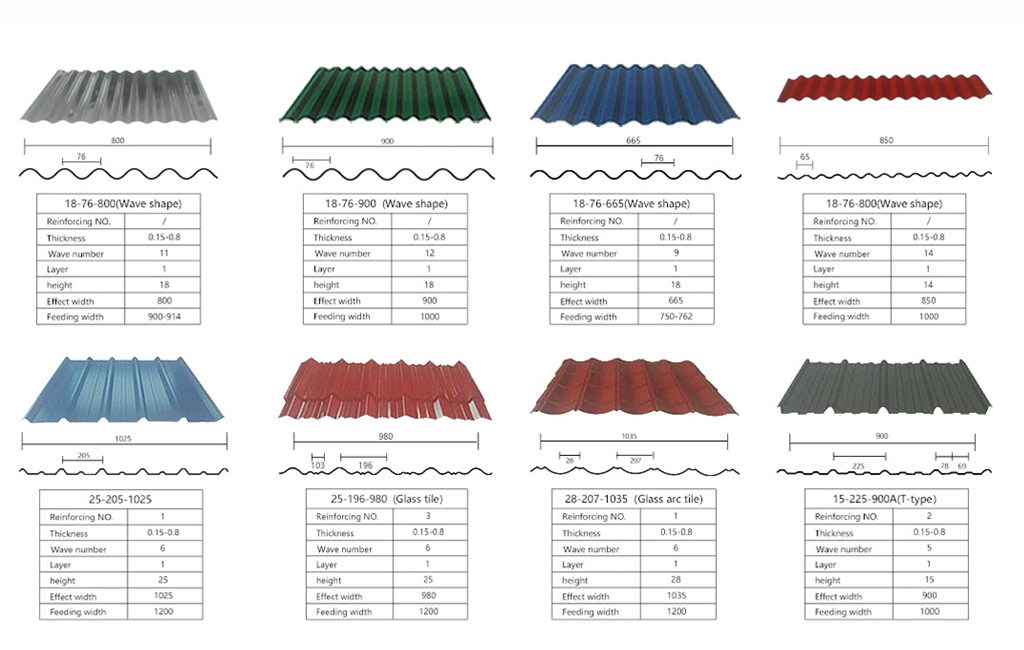

Corrugated Roofing Sheet Type

PPGI Corrugated Sheet Making Process

1. Preparing raw materials: PPGI corrugated sheets are made from galvanized and color-coated steel plates. These steel plates must meet national standards and pass inspection.

2. Steel plate treatment: We use high-quality steel plates to remove rust, clean, and level the surface to make it smooth and free of impurities. 3. Mold design: We design and make molds to make sure the color steel tiles are the right shape and size.

4. Forming process: Put the steel plate in the mold and make the color steel tile through pressing, bending, and other processes.

5. Surface pretreatment: Remove treatments from the color steel tiles to improve coating adhesion and corrosion resistance.

6. Coating: Apply anti-rust paint, topcoat, etc. to color steel tiles to enhance corrosion resistance, waterproofing, UV protection, etc.

7. Curing and drying: The coating dries quickly and is cured by high temperature or ultraviolet irradiation, improving adhesion and durability.

8. Inspection and packaging: Check the color steel tiles for size, appearance, and performance before packaging.

Application

China PPGI roofing sheet is suitable for the decoration of roofs, walls, and interior and exterior walls of industrial and civil buildings, warehouses, special buildings, large-span steel structure houses, fences, activity rooms, industrial factories, residential buildings, parking lots, high-end villas, etc. It has the characteristics of light weight, high strength, rich color, convenient and fast construction, earthquake resistance, fire prevention, rain resistance, long service life, and maintenance free.