- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

Seamless Steel Pipe(SMLS Pipe)

- group name

- seamless steel pipe

- Min Order

- 30 ton

- brand name

- Yuantai Derun Steel Pipe Manufacturing Group

- model

- ytdr-Seamless Steel Pipe

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Thu, 26 Feb 2026 22:23:39 GMT

Paramtents

Certification ISO/CE/ASTM/AS

Delivery time 7-30 days

Tolerance as required

Place of origin China

Thickness 2mm-50mm

Length 0.5-24m or as required

Diameter Φ:21.3mm-914mm

Standard API 5L ASTM A106/A53/A500/A501 EN10210/10219

Grade X42/52/60/65/70 Gr.A/B/C,S275/355/235/420/460

Supply capacity Annual output of 5 million tons

Packging & Delivery

-

Min Order30 ton

Briefing

Seamless Steel Pipe & Tube,Carbon Seamless Steel Pipe,SMLS Pipe & Tube, CS Seamless Pipe,Black Seamless Pipe, GI Seamless Pipe

Detailed

Seamless Steel Pipe(SMLS Pipe)

CS seamless pipe Sizes:

Maximum diameter: 36" (914.4mm) minimum diameter: 1/4" (10.3mm)

Maximum thickness: 60mm mininmum thickness: 2.11mm

SCH: SCH10,SCH20,STD,SCH40,SCH60,XS,SCH80,SCH100,SCH120,SCH160,XXS

Standard of carbon seamless steel pipe

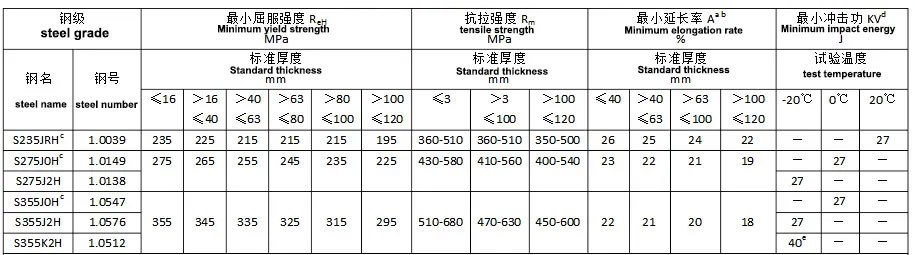

Chemical components & mechanical properties

Classfication of carbon seamless steel pipe

Tolerances of carbon seamless steel pipe

Uses:

Petroleum cracking pipe,Boiler and superheated steam pipe,Boiler Tube,Mechanical structure pipe,Automobile half axle sleeve,Ship pipe,Geological drilling pipe,petroleum pipe,line pipe,Water pipe,Natural gas pipeline,Container tube

Mechanical properties of seamless pipes

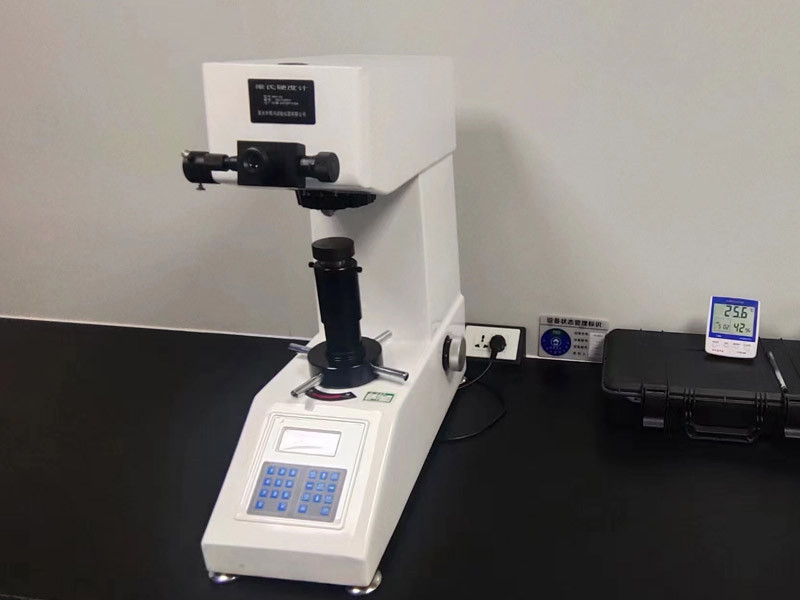

Strict product inspection

Each steel pipe must pass the inspection layer by layer. Only the products that pass the inspection can leave the factory. Never let an unqualified product flow into the market

Seamless steel pipe coating:

|

3PE

|

3PP

|

FBE Coating

|

Epoxy Coating

|

|

Special Painting

|

Galvanization

|

Oiling

|

Painting

|

|

Bare

|

Galvanized aluminum magnesium

|

anticorrosive

|

Black seamless pipe production cycle:

Under normal conditions,3-30 days,It also depends on the quantity and difficulty of production.Can communicate with the account manager.Contact Us now!

Seamless steel pipe Delivery cycle

Southeast Asia generally takes 15 days, South Africa takes 45 days, the Middle East takes 30 days, Europe takes 45 days, Japan takes 5 days, India takes 30 days, North America takes 30 days, Russia's Far East takes 7 days, and South Korea takes 5 days