- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

Schedule 40 carbon steel pipe galvanized pipe ZMA pipe customizable for any length

- group name

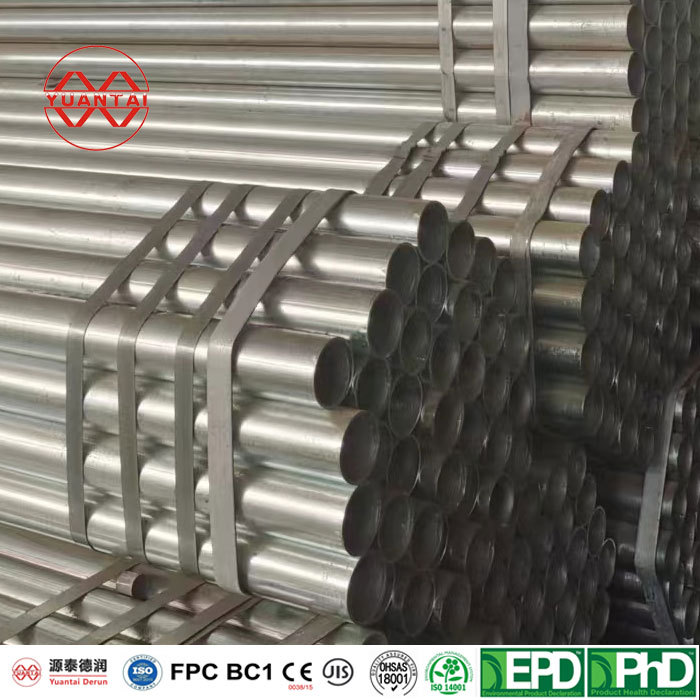

- galvanized steel pipe

- Min Order

- 5 ton

- brand name

- Yuantai Derun Steel Pipe Manufacturing Group

- model

- schedule 40 carbon steel pipe

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Sun, 21 Dec 2025 18:56:48 GMT

Paramtents

Name sch 40 pipe

Delivery time 7-30 days

Tolerance as required

Thickness 0.5mm-16mm

Length 0.5-24m or as required

Diameter round:21.3mm-609mm

Standard API 5L ASTM A106/A53/A500/A501 EN10210/10219

Packging & Delivery

-

Min Order5 ton

Briefing

Yuantai Derun is a large steel pipe manufacturing group that specializes in customizing Schedule 40 Pipes.

Detailed

Schedule 40 Carbon Steel Pipe Galvanized Pipe ZMA Pipe

Overview

Schedule 40 carbon steel pipes are highly regarded in various industries for their excellent performance. Yuantai Derun is a comprehensive manufacturer of carbon steel pipe dimensions schedule 40, Schedule 40 pre-galvanized pipes, and Schedule 40 hot-dip galvanized steel pipes. They offer customization options for caliber, wall thickness, length, surface treatment, pipe end treatment, labeling, spraying, punching, and pipe end threading.

Galvanized Carbon Steel Pipe Dimensions Schedule 40

Schedule 40 Pipe size chart, dimensions, wall thickness and weight for hot dip galvanized steel pipe,pre galvanized steel pipe,Zinc aluminum magnesium coated steel pipes.The dimensions of these steel pipes only represent a portion of the factory's models. If you want a comprehensive model specification table, please contact our customer manager immediately.

Galvanized Schedule 40 Steel Pipe Specification | |||||

Outerside Diameter(inch) | Wall Thickness(mm) |

NO of pieces per bundle | Length(M) |

Weight per piece(Tons)

|

Weight per bundle(Tons)

|

1.2 inch | 2.0 | 91 | 6 | 0.013 | 1.03 |

1.2 inch | 2.5 |

91 | 6 |

0.014

|

1.29

|

1.2 inch | 3.0 | 91 | 6 | 0.016 | 1.54 |

1.2 inch | 3.25 |

91 | 6 |

0.018

|

1.66

|

1.2 inch | 3.5 | 91 | 6 | 0.019 | 1.78 |

1.5 inch | 1.7 | 91 | 6 | 0.0109 | 1.00 |

1.5 inch | 2.0 | 91 | 6 | 0.0129 | 1.18 |

1.5 inch | 2.2 | 91 | 6 | 0.0142 | 1.30 |

1.5 inch | 2.5 | 91 | 6 | 0.016 | 1.47 |

1.5 inch | 2.75 | 91 | 6 | 0.0177 | 1.62 |

1.5 inch | 3.0 | 91 | 6 | 0.019 | 1.76 |

1.5 inch | 3.25 | 91 | 6 | 0.0209 | 1.90 |

1.5 inch | 3.5 | 91 | 6 | 0.0224 | 2.04 |

1.5 inch | 3.75 | 91 | 6 | 0.0239 | 2.18 |

1 inch | 1.7 | 127 | 6 | 0.0075 | 0.96 |

1 inch | 2.5 | 127 | 6 | 0.011 | 1.40 |

1 inch | 2.75 | 127 | 6 | 0.012 | 1.54 |

1 inch | 3.0 | 127 | 6 | 0.013 | 1.67 |

2.5 inch | 1.7 | 37 | 6 | 0.0174 | 0.65 |

2.5 inch | 2.0 | 37 | 6 | 0.0206 | 0.77 |

2.5 inch | 2.5 | 37 | 6 | 0.0259 | 0.96 |

2.5 inch | 2.75 | 37 | 6 | 0.0285 | 1.06 |

2.5 inch | 3.0 | 37 | 6 | 0.0311 | 1.15 |

2.5 inch | 4.0 | 37 | 6 | 0.0413 | 1.53 |

2 inch | 2.0 | 61 | 6 | 0.0163 | 1.00 |

2 inch | 3.75 | 61 | 6 | 0.0304 | 1.86 |

3 inch | 2.5 | 37 | 6 | 0.0305 | 1.13 |

3 inch | 4.75 | 37 | 6 | 0.0576 | 2.14 |

4 inch | 2.5 | 19 | 6 | 0.0396 | 0.75 |

4 inch | 4.5 | 19 | 6 | 0.0713 | 1.36 |

5 inch | 3.0 | 19 | 6 | 0.0588 | 1.12 |

5 inch | 4.5 | 19 | 6 | 0.0882 | 1.68 |

6 inch | 4.75 | 19 | 6 | 0.11 | 2.10 |

8 inch | 3.0 | 7 | 6 | 0.092 | 0.65 |

8 inch | 4.75 | 7 | 6 | 0.147 | 1.03 |

8 inch | 5.0 | 7 | 6 | 0.155 | 1.09 |

8 inch | 5.5 | 7 | 6 | 0.170 | 1.20 |

8 inch | 5.75 | 7 | 6 | 0.178 | 1.25 |

... | ... | ... | ... | ... | |

>Size Of Schedule 40 HDG Carbon Steel Pipe

The schedule shows the dimensions and pressure capacities of the pipes.Schedule 40 carbon steel pipes come in multiple sizes to choose from, suitable for different applications. The standard size range is from 1/8 "to 24" nominal diameter, and a range of specifications can be selected according to the required pressure level.

Grades Of Schedule 40 Carbon Steel Pipe Galvanized Pipe

>>>>ASTM A53 Grade B

>>>>ASTM A106 Grade B

>>>>API 5L Grade B

>>>>ASTM A333 Grade 6

>>>>ASTM A500 Grade B

>>>>ASTM A501 Grade B,etc

Benifit of Galvanized Carbon Steel Pipe Schedule 40

1.HIGH STRENGTH: Schedule 40 carbon steel tubes and galvanised tubes are renowned for their superior strength and are suitable for applications where strength is required.

2. Corrosion Resistant: Schedule 40 carbon steel galvanised pipe is extremely corrosion resistant and suitable for both indoor and outdoor applications.

4. Versatility: Schedule 40 galvanised carbon steel pipe can be used in a variety of applications, including pipelines, oil and gas transportation and structural applications.

5.Cost-effectiveness:Carbon steel pipe schedule 40 is a cost-effective material. It has a long service life, requires minimal maintenance, and is easy to use. This makes it an economic choice for various industries compared to other materials.

Application Of Schedule 40 Galvanized Carbon Steel Pipe

Schedule 40 galvanised carbon steel pipes are widely used in various industries. Some of the common uses include:

1. Structural support systems for residential, commercial, and industrial buildings.

2. Oil and natural gas pipelines.

3. Steam and water supply systems.

4. Scaffolding.

5. Agricultural machinery structure.

6. Automotive manufacturing and exhaust systems.

Order form and process for Schedule 40 carbon steel pipes

Yuantai Derun is one of the largest Schedule 40 steel pipe factories in China, capable of producing various galvanized steel pipes at affordable prices and of superior quality. We accept OEM/ODM/OBM. We accept mass customization, and the order process is as follows: consultation ->quotation ->contract signing ->deposit remittance ->production - quality inspection ->package ->payment of final payment ->shipment

Material Composition

Schedule 40 carbon steel pipes are mainly made of carbon steel, which contains iron and carbon as the main elements. In addition, there may be small amounts of other elements such as manganese, silicon, sulfur, phosphorus, and so on.

Pressure Rating

Schedule 40 carbon steel casing pipes have different pressure ratings depending on their size. They can withstand high pressure levels, so strict requirements exist for the appropriate pressure level of the pipeline.

Product testing

Before leaving the factory, steel pipes undergo several inspections. Only those that pass the inspection are approved for sale. The use of moulds can result in unqualified products entering the market.

Size Measurement

Yield and Tensile Strength Testing

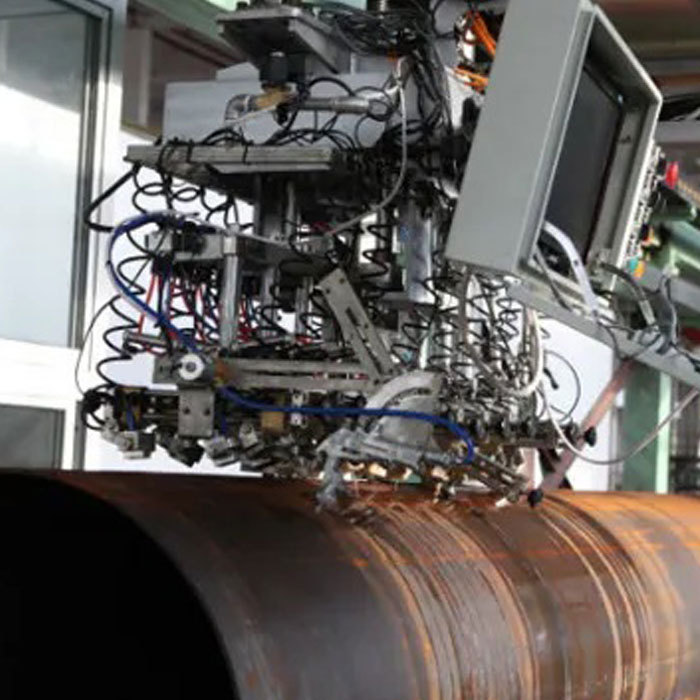

X-ray Test

Salt spray test

Chemical Composition Testing

Hardness Testing

Hydrotesting

Impact testing

Choose a suitable supplier of schedule 40 carbon steel pipes

Experience

When choosing suppliers of Schedule 40 Carbon Steel Pipe, it is important to consider their importance and experience in the industry. Experienced and reputable suppliers are more likely to provide high quality products and reliable services.

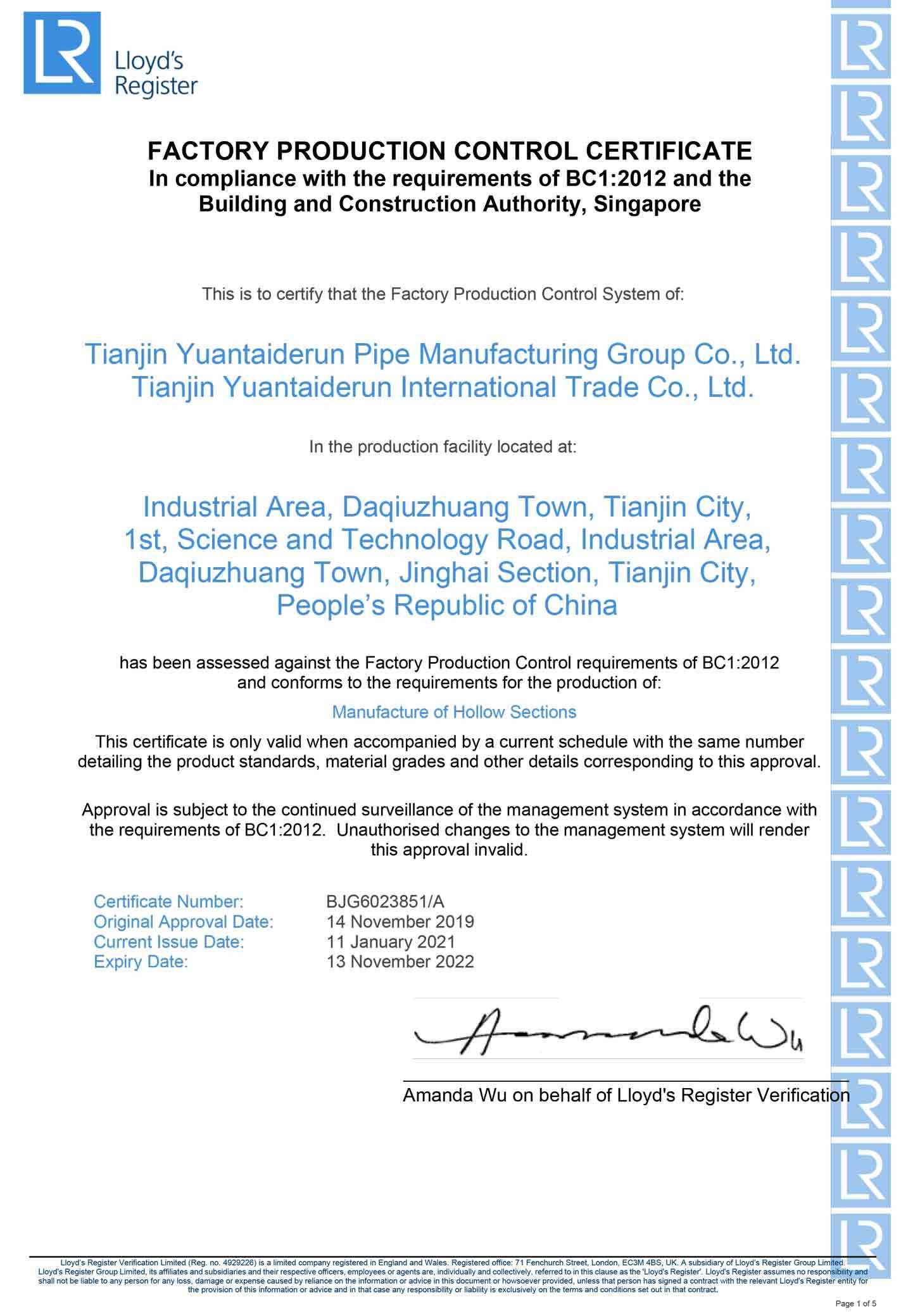

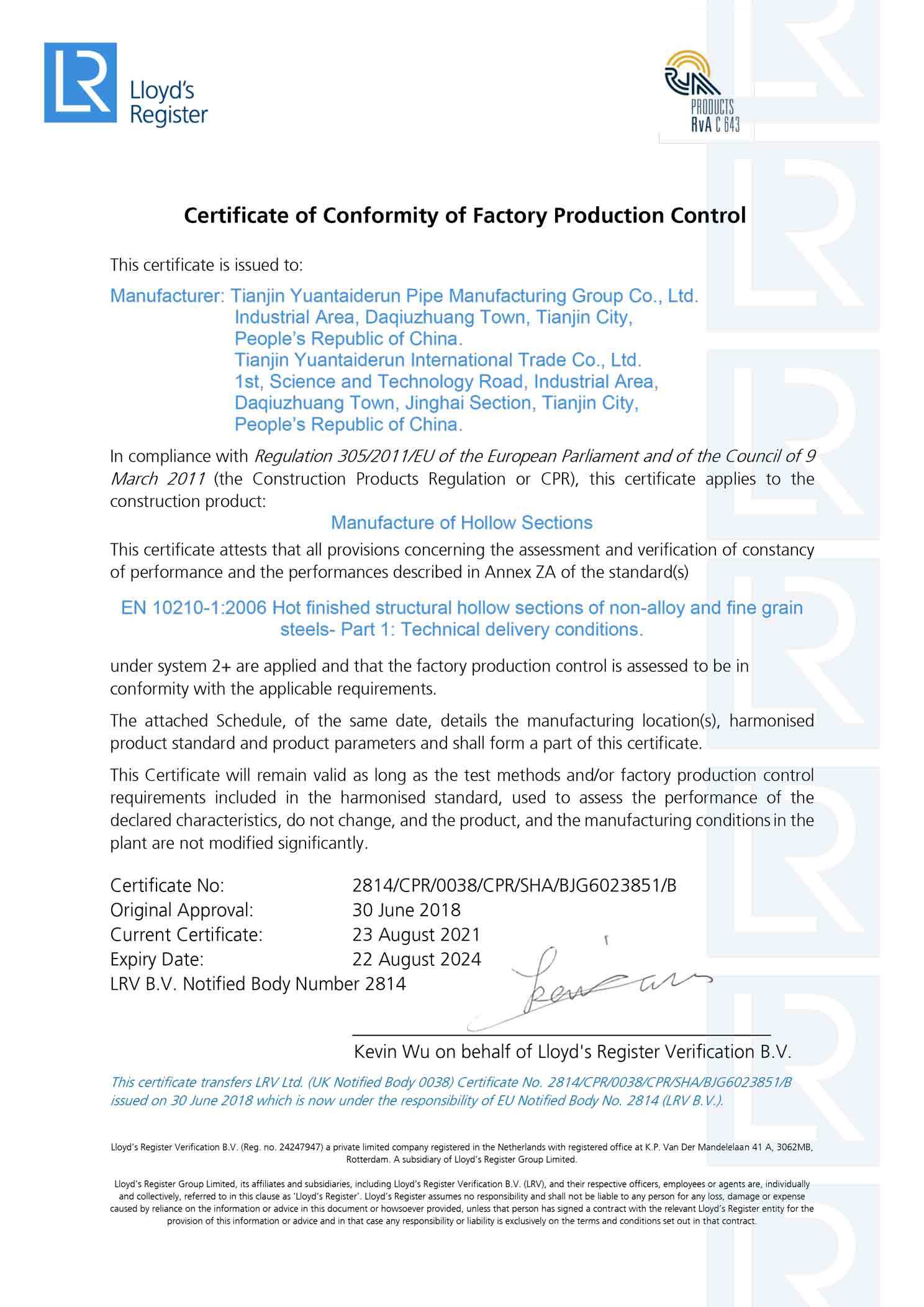

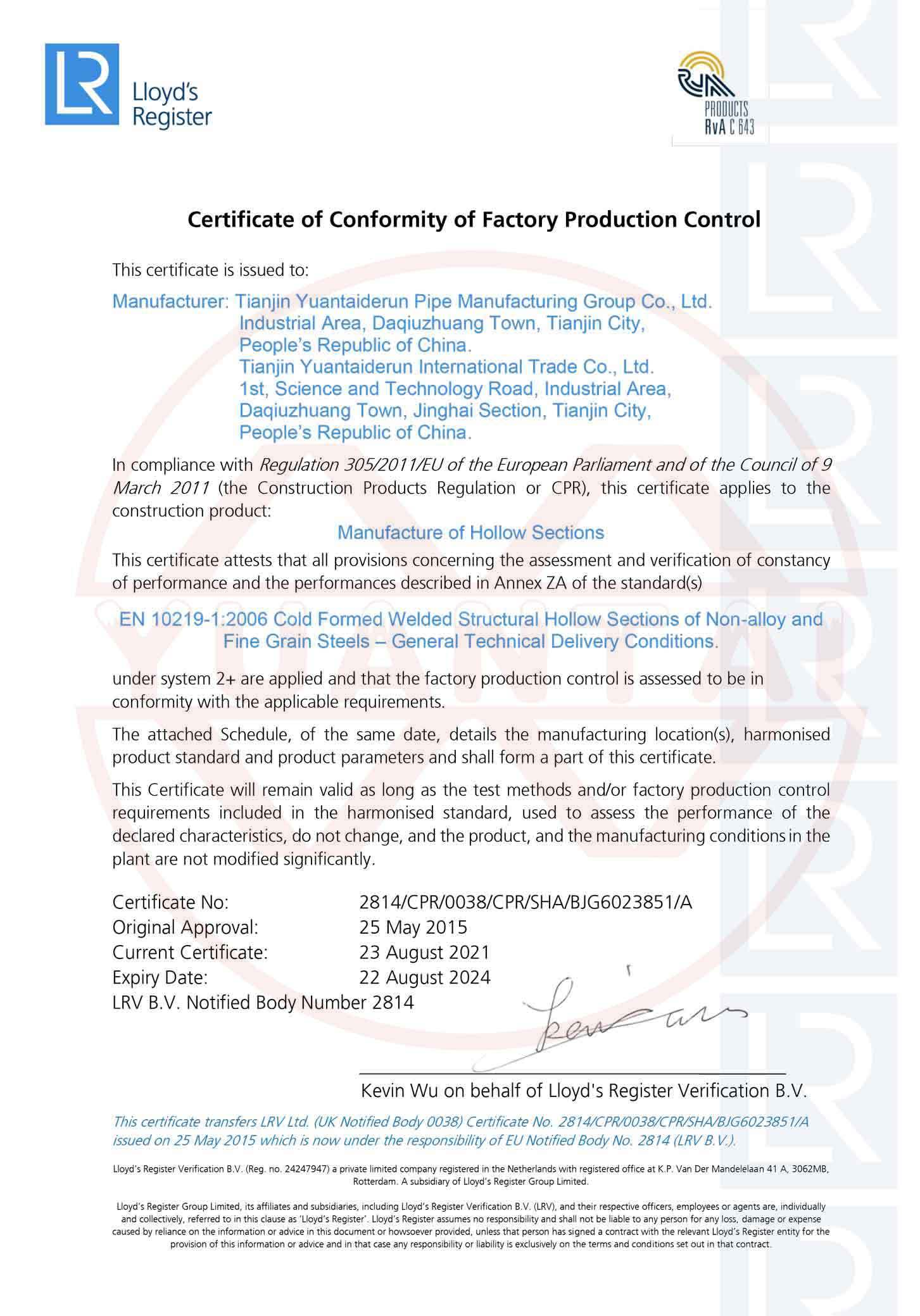

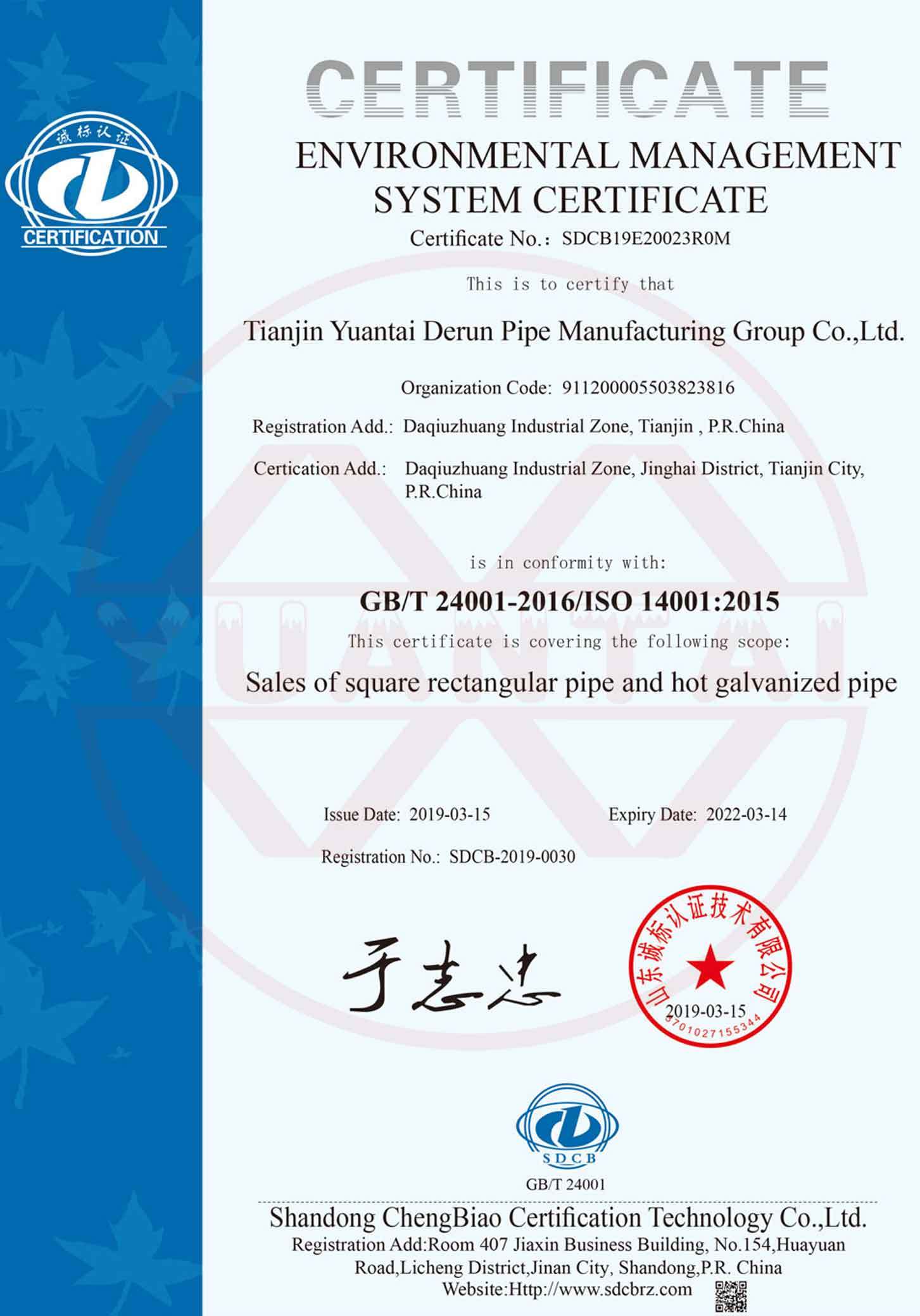

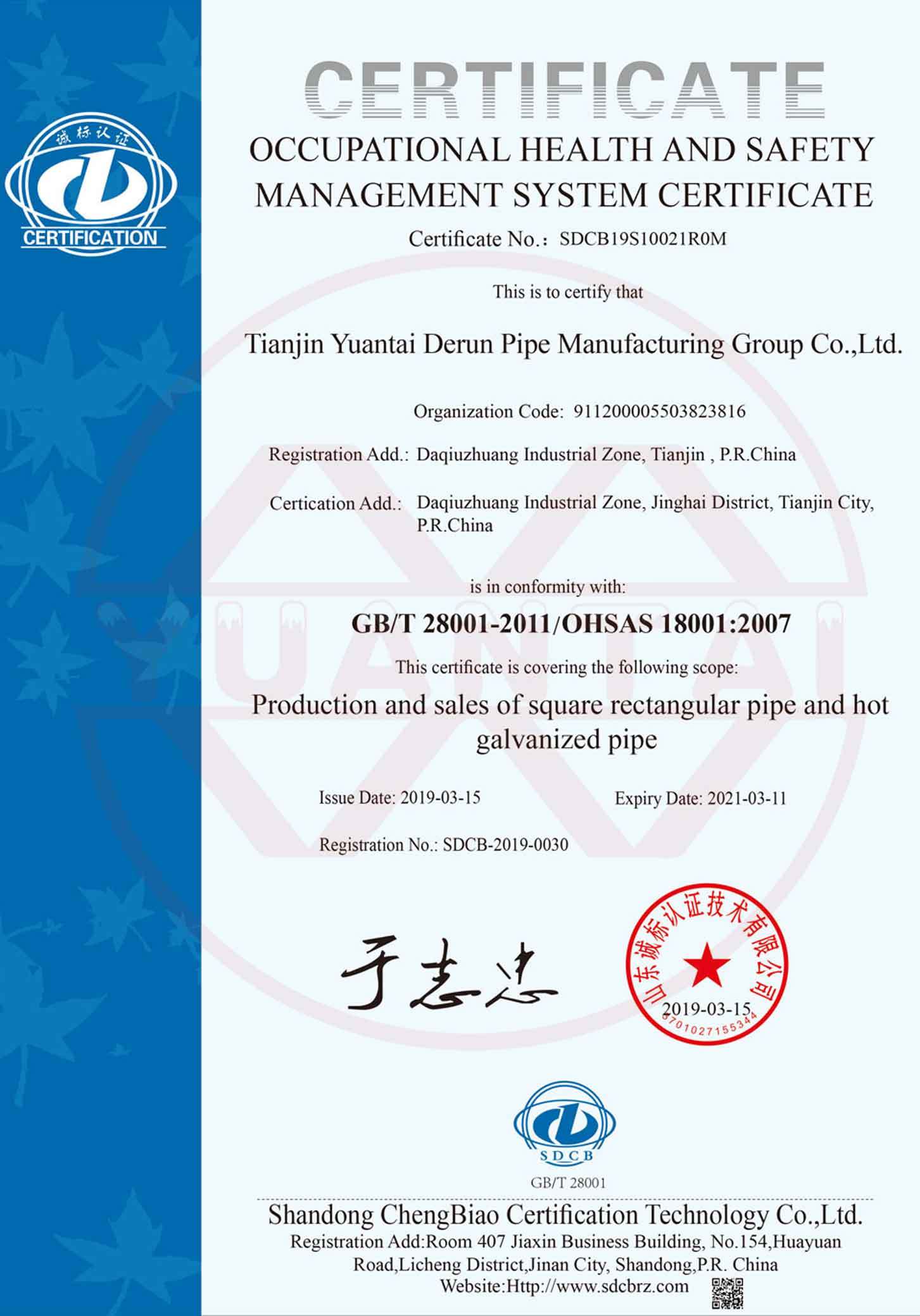

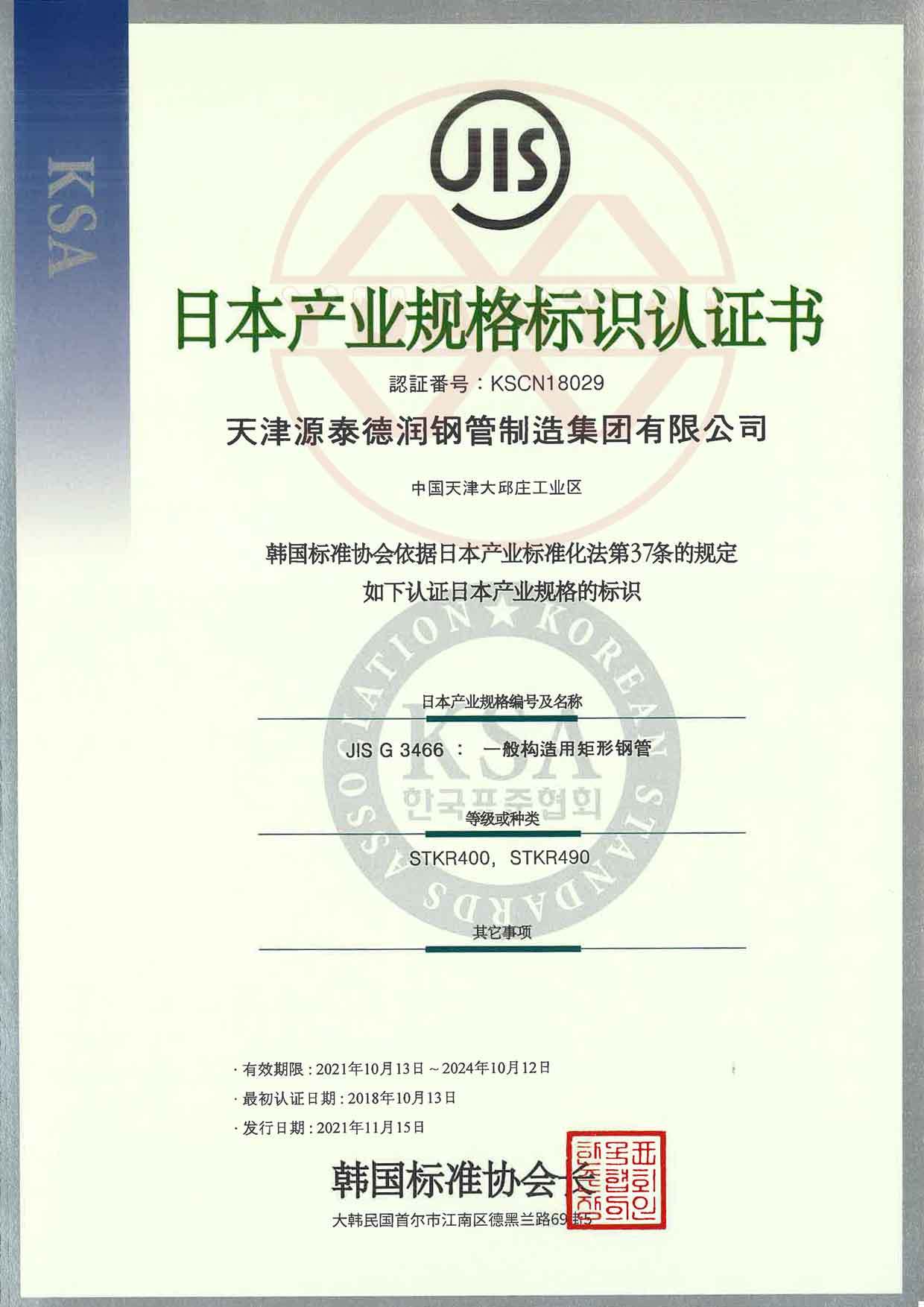

Certification and compliance

Ensure that suppliers are certified and comply with relevant industry standards and regulations. This ensures that the supplied Schedule 40 Carbon Steel Pipe meets the necessary quality and safety requirements.

Customer service

Good customer service is crucial when choosing a supplier. Look for a supplier that is responsive, delivers on time and provides after-sales support, including technical assistance and warranty options.

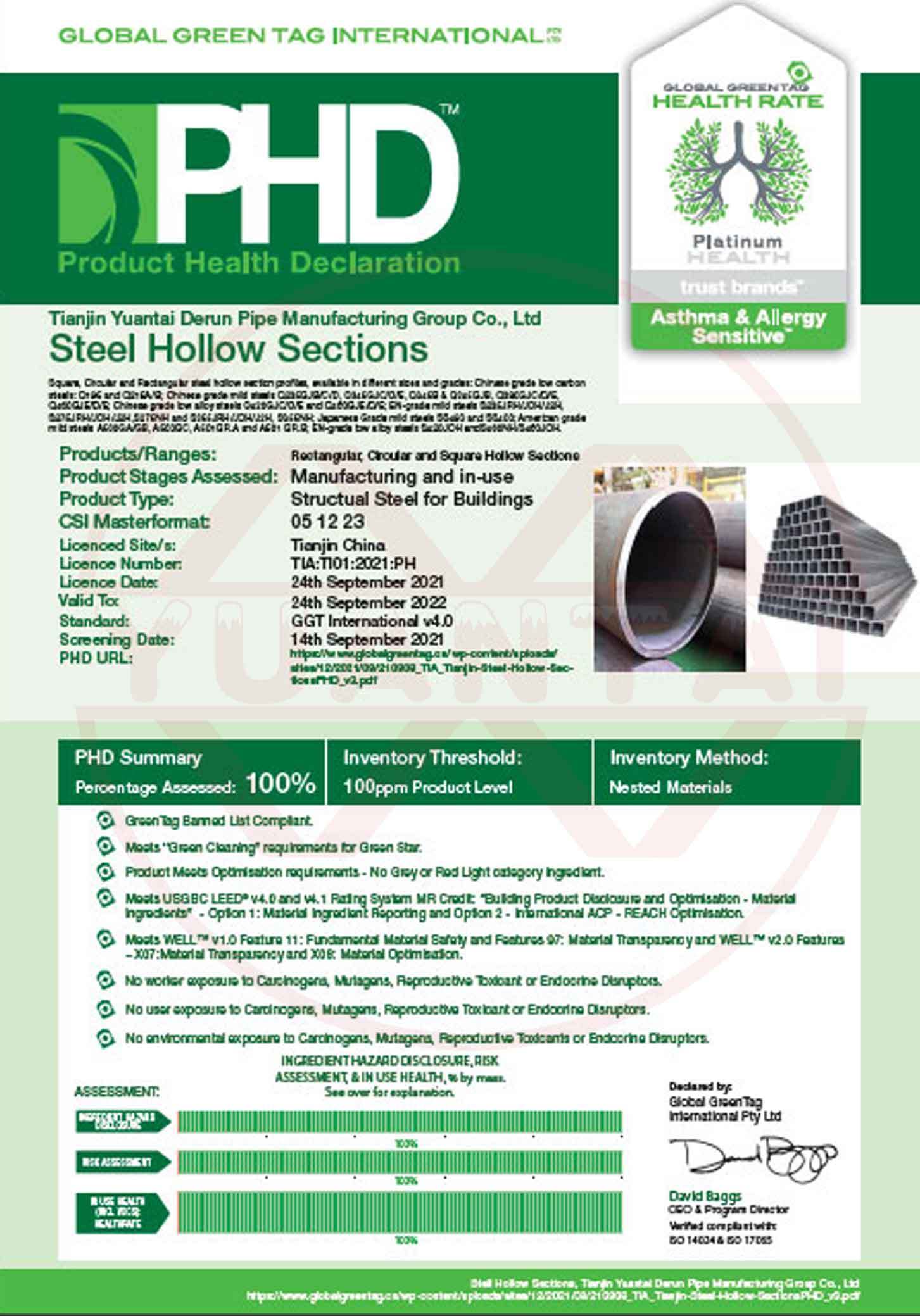

Certification

BC1

EN10210

EN10219

BV

EPD

PhD

ISO14001(GB/T 24001)

OHSAS18001(GB/T28001-2011)

ISO9001(GB/T19001)

JIS G3466