- Home

- About us

- Products

- square steel pipe

- rectangular steel pipe

- round steel pipe

- shaped tube

- LSAW steel pipe

- zinc aluminium magnesium coating steel pipe

- galvanized steel pipe

- ERW steel pipe

- seamless steel pipe

- spiral steel pipe

- LINE PIPE&OCTG

- stainless steel pipe

- steel coil

- steel plate

- ship building steel pipe

- photovoltaic bracket

- steel profile

- u channel

- Faqs

- News

- Certificate

- Contact us

hot rolled steel angle

- group name

- steel profile

- Min Order

- 2 ton

- brand name

- Yuantai Derun Steel Pipe Manufacturing Group

- model

- hot roll steel angle

- Nearest port for product export

- XINGANG PORT TIANJIN CHINA, TANGSHAN CHINA, SHANGHAI CHINA, DALIAN PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Sun, 15 Feb 2026 05:21:01 GMT

Paramtents

steel grade s275jr/s355jr,etc

Packging & Delivery

-

Min Order2 ton

Briefing

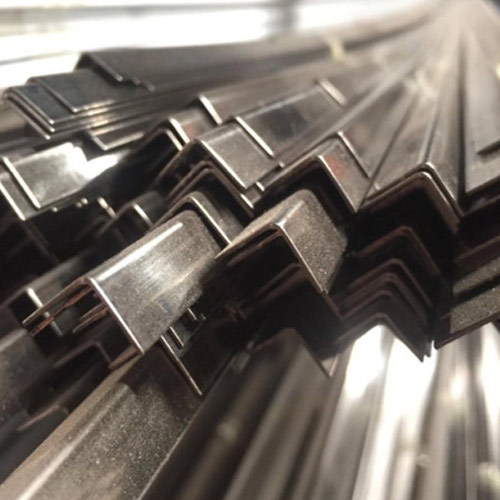

Yuantai Derun is a large hot rolled steel angle supplier in China.It is a type of angular steel made through the hot rolling process.

Detailed

Hot Rolled Steel Angle

Hot Rolled Steel Angle is a type of angular steel made through the hot rolling process. It is commonly used in building and structural projects and has high strength and good toughness. Hot rolled steel angle can be either equal or unequal angles, with common sizes and specifications to meet a variety of engineering needs.Yuantai Derun hot rolled angles have stable performance and accurate dimensions, and can be cut to length for users on request.Yuantai Derun is a big china hot rolled steel angle supplier in Tianjin. Sent Your Inquiry Now

Standards: GB/T 9787-2008, GB/T 706-2008, JIS G3101, ASTM A36,etc

Finish: black (reflective) or galvanized.

Material: Carbon Steel/Alloy Steel /Stainless Steel

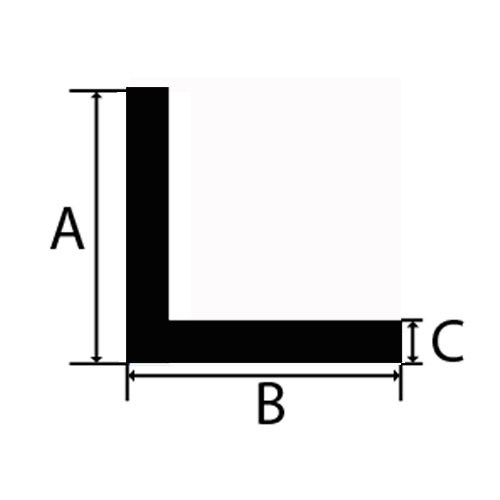

Specification: side length 20mm-200mm, thickness 2mm-24mm.

Applications: construction, machinery manufacturing, automobile manufacturing, railroads, bridges, etc.

Length: usually 6 or 12 meters.

Delivery condition: Hot rolled (AR OR WAR) / Normalized or normalized rolled (N) / Thermomechanically rolled (M)

Legs: Equal or unequal

Hot Rolled Steel Angle Sizes

Hot rolled steel angle dimensions are{A×B×C(inch)}:0.5×0.5×0.125-8.0×8.0×1.0,and the hot rolled steel angle length :0.5-12M or customized according your need.Because there are standard and non-standard sizes of hot rolled steel angle, users can customize the size of the sizes according to the actual needs of their projects. Contact us now to send your customized size requirements.

Hot rolled steel angle sizes include 1 x 1 hot roll steel angle, 2 X 2 X 1/8 A36 Steel Angle, 3 X 3 X 1/2 A36 Steel Angle, 6 X 6 X 3/8 A36 Steel Angle and more.

Hot Rolled Steel Angle Type

Hot Rolled Steel Angle can be divided into steel equal angle hot-rolled and Unequal Hot Rolled Angle steel according to the side length. According to the surface coating treatment, can be divided into black hot rolled steel angle bar and hot rolled galvanized steel angles. According to the chemical composition, can be divided into hot rolled mild steel angle, hot rolled carbon steel angle, hot rolled stainless steel angle, alloy angle, etc..

Black Hot Rolled Steel Angle Bar

Hot Rolled Galvanized Steel Angles

Hot Rolled Mild Steel Angle

Hot Rolled Stainless Steel Angle

Hot Rolled Steel Angle Price

The quotation of hot rolled angle is especially dependent on the price of raw materials, so the quotation of hot rolled angle are floating and changing. If you need a specific quote, you have to contact our account manager to give the current price. With the affordable price and guaranteed product quality, you can rest assured to place your order for hot rolled angle steel from Yuantai Derun.

Hot Rolled Steel Angle Characteristics

Welding: good

Machining / Grinding: good

Bending / Forming: Fair

Wear Resistance: Fair

Corrosion Resistance: Poor.

Hot Rolled Steel Angle Manufacturing Process

Hot rolled angle steel molding process mainly includes the following steps: raw material preparation, heating, rolling, cooling and finishing.

1. Raw material preparation: the raw material is usually steel billet, which can be pig iron, steel ingots or scrap steel. The billet is pre-treated to achieve the right size and shape.

2. Heating: The pre-treated billet is put into the heating furnace for heating. After heating to a certain temperature, the billet reaches sufficient plasticity to be rolled in the next step.

3. Rolling: The heated billet is fed into the rolling mill for rolling. The mill exerts pressure on the billet through rolls to deform it into the shape of an angle.

4. Cooling: After the angle is rolled, it needs to be cooled quickly to prevent deformation caused by heat treatment.

5. Finishing: The cooled angle needs to be measured in size to ensure that its specifications and quality meet the requirements. If there is any deviation, corresponding measures need to be taken to adjust.

Hot Rolled Steel Angle Surface Treatment

Due to the fact that most of the materials used for hot-rolled angle steel are carbon steel, which is not corrosion-resistant, in order to increase the corrosion resistance of angle steel, you can choose the following surface treatment methods.

1.Hot Dipped Galvanizing -> hot rolled galvanized steel angles

2.Hot Dip Galvanized Aluminum Magnesium->hot rolled galvanized aluminum magnesium steel angles

These two surface treated hot-rolled angle steels have excellent corrosion resistance and extended service life.

Contact us immediately to learn more.

Hot Rolled Steel Angle Application

Hot rolled angles are used in a wide range of common applications:

1. steel structure

2. door and window frames

3. shelves

4. agricultural equipment frames

5. fence guardrail

6. home decoration

7. sheet piling

8. steel and wood furniture

9. columns

FAQ:

How to calculate the weight of hot rolled Steel angle?

The actual weight of hot rolled angle must be weighed by weighing. Formula for calculating the theoretical weight of hot rolled angle:Calculation formula for size and weight of hot rolled equal-edge angle:W(kg/m)=0.00785*Side thickness*(2 side width - side thickness)

hot rolled steel angle tolerances

Thickness Tolerance:

Generally, the thickness should not deviate more than ±3% from the specified nominal thickness.

Length Tolerance:

The length tolerance for hot-rolled angles is typically ±1/8 inch for lengths under 20 feet, and ±1/4 inch for lengths over 20 feet.

Width Tolerance:

Width tolerances may vary, but it's common to see tolerances of ±1/16 inch.

Leg Length Tolerance:

For the leg lengths of the angles, tolerances are generally within ±1/8 inch.

Straightness:

The allowable deviation from a straight line (usually over a length of 10 feet) is typically around 1/4 inch.

Twist:

The allowable twist in a steel angle is often specified as a maximum of 1/8 inch per foot of length.

Camber:

The allowable camber or bend in a hot-rolled steel angle is often specified and can vary depending on the application, but it is generally limited to a certain amount (not exceeding 1/8 inch per 10 feet).

How To Choose hot rolled steel angle factory?

You can find reviews and customer feedback about hot rolled steel factories online. Look for reviews about product quality, delivery time, and other aspects of the manufacturer's credibility and reputation.

What are the steel grades of hot rolled Steel angles?

s275jr,s355jr,Q235B、Q235C、Q235D、Q355B、Q355C、Q420B、Q420C,ASTM A36,SS400,SS540,St37-2,etc.

What is the typical strength of hot rolled steel angles?

1. Tensile strength:

Q235B: 370-500 MPa

Q345B: 490-675 MPa

SS400: 400-510 MPa

SS540: 540 MPa or more

St37-2: 340-470 MPa

2. Yield strength:

Q235B is 235 MPa, Q345B is 345 MPa, SS400 is 245 MPa, SS540 is over 390 MPa, and St37-2 is 235 MPa.

3. Elongation:

Q235B: 24% elongation.

Q345B: 21% elongation.

SS400: 21% elongation.

SS540: 16% elongation.

St37-2: 25% elongation.

4. Bending strength depends on the edge length, broken area, and steel composition, material, and structure. Choose the right angle specifications and processes for the job and use the right bending control technology.